Do you want to make your customers happy? Eliminate their brake noise. Of all the things that will draw unwanted attention to their car, squeaks, groans or chirps when they step on the brake pedal will likely be high on the list of what brings them into your shop.

Your customer only cares about the noise, but as professionals, it’s important that we understand the roots of noise, vibration and harshness, or NVH in brake systems.

As brake pads clamp onto a rotor, high frequency mechanical vibrations are initiated, setting off a chain reaction that excites the surrounding air. This vibration generates audible cyclic frequencies generating pressure changes that eventually reach our ears. The origins of these vibrations and the resulting noise begin in the interaction between the brake pads and rotors. And while brake rotor finish, pad selection and hardware are crucial, the key to silencing brake noise lies in executing the brake job correctly from the start.

Establishing a diagnostic process for potential noise issues ensures a resolution and customer satisfaction the first time, every time.

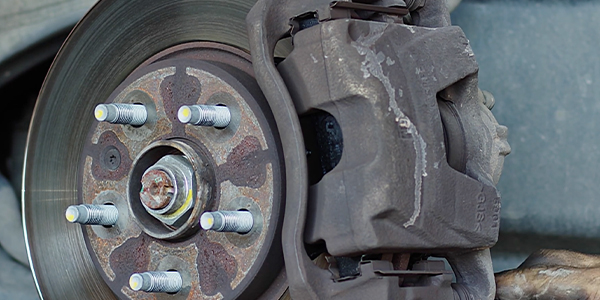

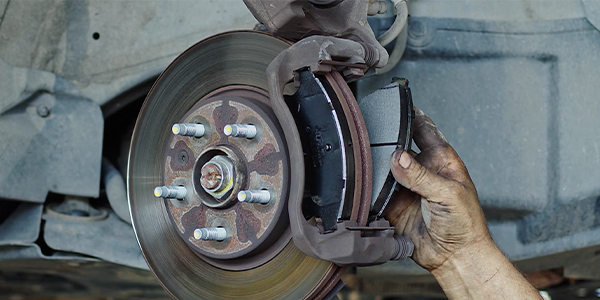

Once in the shop, each caliper should be removed for a thorough inspection of pads, rotors, hardware, caliper slides and calipers. Choosing friction materials with consistent coefficients of friction across various conditions, and those that leave a transfer layer on the rotor surface, can minimize excitation and noise. OE pad recommendations are the best place to start.

The quality of rotor finish plays a pivotal role in noise prevention as well. Achieving a smooth surface finish measured in terms of roughness average – or RA – is crucial for optimal brake performance. Resurfaced rotors should be rinsed with water to prevent residual metal particles from embedding into the pad. And a non-directional finish aids in the bedding-in process and prevents rotor grooves from affecting pad movement.

Brake hardware should always be replaced as well as worn slide pins and boots and proper lubrication should be used in the proper locations.

When contact with the brake pads has worn grooves into the caliper brackets or steering knuckles, it means those components simply need replaced. Bedding-in brake pads with the intended rotor is essential for maximizing brake performance. Following the manufacturer’s recommended procedures ensures a smooth transfer film on the rotor, minimizing brake shudder. While there are no universal rules for bedding-in procedures, each manufacturer provides specific guidelines tailored to their manufacturing processes.

There are no miracle ointments or cures to silence brake noise, but doing the job right is as good as you’ll get. High quality rotor finishes and stable friction materials, a comprehensive understanding of brake systems and meticulous attention to rotor finish, brake pad selection and adherence to manufacturer guidelines will help prevent and resolve brake noise issues.

Thanks for watching.