In today’s professional shop environment, you’re often the bridge between the shop owner, the technician and the customer. You need to field questions about what’s right for a wide range of applications – today, I’ll help answer some questions about what to look for in a quality wheel hub assembly.

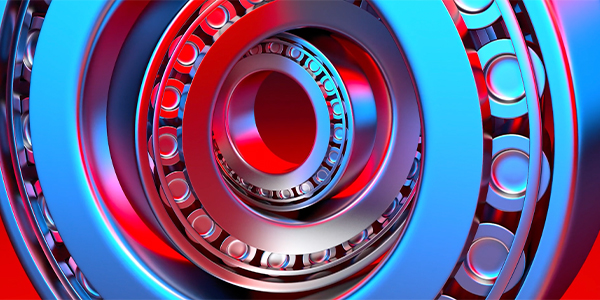

What wheel bearings do hasn’t really changed over the history of the automobile. Wheel bearings allow for the friction-free movement and rotation of the wheel. One side of the bearing is attached to the vehicle’s suspension, while the other side rotates with the wheel.

What HAS changed is how they do it. You’ll generally hear about the evolution of wheel bearings in terms of Generation 1, 2 and 3. Generation 3 bearings, which you’ll find on most late-model vehicles today, are self-contained, greased and sealed hub assemblies that contain the bearing, wheel-speed sensor or tone ring and a flange for mounting the wheel and rotor. These bolt-on HUB ASSEMBLIES are much easier to install compared to their predecessors and do not require any adjustment over their service life.

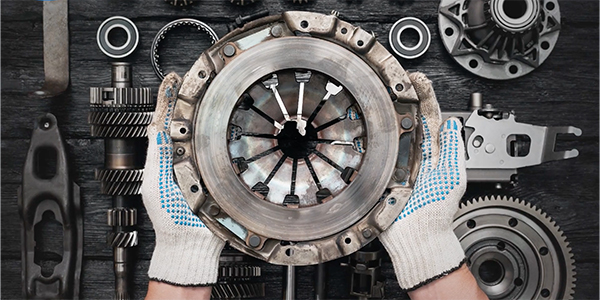

The fundamental components of a hub assembly include the spindle, the main body of a wheel hub – where the wheel and brake rotor mount. It includes a raceway to support the outboard set of rolling elements. You also have the outer race, which bolts to the steering knuckle and sits between the spindle and the inner race. The inner race is the top piece of the assembly. It includes a raceway to support the inboard set of rolling elements. The spindle is roll-formed onto the inner race to lock it into the assembly.

The two types of rolling elements are ball-bearing rollers, which are used in most passenger vehicles and tapered roller bearings, which you’ll usually see in larger, heavier vehicles. Regardless of their design, they’re held in place by a cage, and they allow the rotation between the outer race and the spindle – and by extension, between the wheel and the knuckle.

The primary reason hub bearings fail is simple – vibration. But what causes that vibration is what’s really important. Vibration is just a symptom of many potential factors, including contamination, wear, impacts like a curb strike and overheating. The classic sound associated with a bad bearing is a grinding noise that changes with vehicle speed, typically while accelerating above 30 mph. But, a bad wheel bearing can produce a number of other unpleasant sounds. A rumbling, growling, humming, chirping or cyclic noise of any kind from the vicinity of the wheels can be a good indication that the bearings need to be inspected without delay.

What makes a QUALITY hub unit that can stand up to the wheel forces, heat and loads that put these critical wheel-end components to the test? The hub SPINDLE is a great place to start. Increasing the thickness of the flange on the spindle adds strength to protect it from warping under impact and safeguards it against vibration due to runout.

How about the SEALS? Hub-bearing seals keep lubricating grease in and contaminants out, and they play a critical role in the service life of the hub assembly. The inboard seals on a quality hub assembly will feature multiple sealing lips that redirect contaminants out, and they might introduce a metal shield over the top of the seal. And premium hubs will have robust outboard multi-lipped seals and better shielding.

Another important factor is the spindle DESIGN. Engineered hub assemblies will incorporate a roll-form design that pre-applies the bearing loading. This makes the hub less reliant on the torque applied to the axle nut, ensuring the longest service life possible.

Gen 3 hub assemblies often include a wheel-speed sensor, which is critical to the operation of the antilock braking system and other vehicle safety and telematic systems. They’re not all alike. A low-quality wheel-speed sensor that does not match the OEM for signal type and output can contribute to hub failure, which is why premium hub assemblies not only generate the correct signal but also increase the THICKNESS of the wire sheath and add strain reliefs to protect the wires, ensuring accurate and continuous wheel-speed-sensor function. This is important on late model vehicles equipped with Advanced Driver Assistance System or ADAS features.

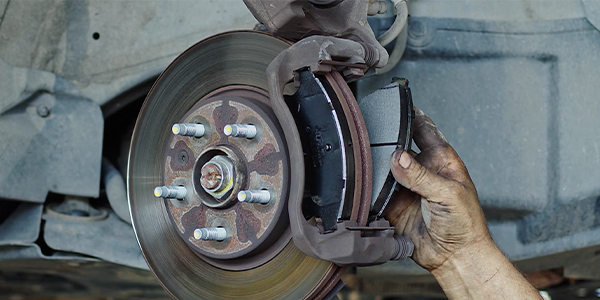

Finally, installation is made quicker and complete when the fastening hardware such as steering-knuckle bolts and axle nuts as well as torque values are included in the box. Using the correct torque values and a torque wrench, instead of an impact gun, are best practices technicians should always follow.

TTX hub assemblies are precision-built to handle high heat and heavy loads, and the rolling elements and raceways are optimized to excel under these conditions. Mevotech utilizes Generation 3 ORBITAL ROLL-FORMING for a set preload right out of the box and increased assembly stiffness that reduces potential vibration and improves part life. Mevotech’s QUANTUM SEALING SYSTEM utilizes multi-lipped seals at both inboard and outboard ends to create a layered defense against road contaminants and keep vital lubricating grease inside. Speaking of grease, the advanced pre-filled NANOCERAMIC GREASE reduces friction, resists corrosion, retains viscosity at high and low temperatures and withstands water ingress, while micro-polishing rolling elements.

On the outside, the REPEL-TEK heavy duty anti-corrosion formula protects the entire assembly and hardware, making removal of components such as wheels and rotors easier and preventing build-up of salt, grime and other road wash. And the extra-durable, abrasion-resistant wheel-speed-sensor cable ensures wheel-speed-signal integrity at all times.

As a service advisor you’re often the one selecting the replacement hub assembly. Make you you’re recommending one that meets the installation needs of your technician, the reliability needs of your shop and the vehicle needs of your customer.

Thanks for watching.