When it comes to replacement suspension parts are OE parts necessarily superior to the aftermarket offerings? In shops all over the country the debate rages. Which side of the argument do you fall?

In the realm of replacement suspension parts, the battle between OEM and aftermarket options rages on. Each side champions its own virtues, leaving consumers and technicians to ponder which route to take.

OEM parts prioritize factors like weight, initial quality, and cost-effectiveness. These components are designed with the vehicle’s original specifications in mind, aiming to ensure optimal performance and safety. However, they may not always address potential weak points that become apparent after the warranty period expires.

Conversely, the aftermarket sector focuses on creating solutions that enhance the longevity of repairs. Premium suspension components from leading aftermarket manufacturers often offer significant improvements over factory-installed parts. Even seemingly minor enhancements can translate into substantial gains for technicians and customers alike.

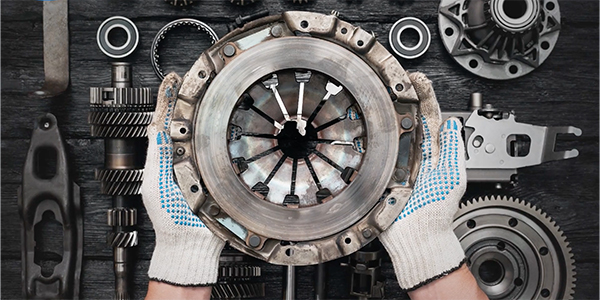

Consider ball joints, for instance. Engineered enhancements such as increasing the size of the ball and socket can directly impact longevity and performance. A larger joint distributes load more effectively, resulting in a longer service life. Moreover, the material composition of the ball and socket, coupled with the correct grease, plays a crucial role in maintaining optimal functionality.

Engineered replacement options prioritize serviceability and durability. Utilizing materials like sintered metal for bearings and the ability to flush out old grease and contaminants, these components offer enhanced longevity compared to traditional polymer joints. Regular servicing, such as during a vehicle oil change, can extend their lifespan significantly, providing a cost-effective solution in the long run.

The construction and materials used in suspension components also warrant consideration. While stamped steel has been a staple for decades, it is prone to corrosion. In contrast, cast control arms, whether iron or aluminum, offer increased durability and resistance to corrosion. Upgraded the design from the original stamped to a solid cast component can enhance the longevity of critical parts, especially in high-stress applications like pickup trucks or SUVs.

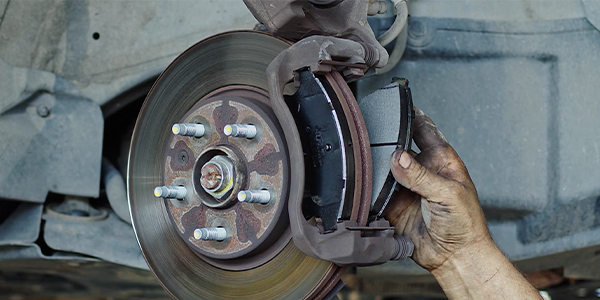

Ease of installation is another crucial factor to consider. OEM parts often come without replacement fastening hardware, necessitating additional costs. Moreover, some components are not available separately, requiring the purchase of entire assemblies. Aftermarket solutions excel in this regard, providing not only the necessary parts but also innovative tools to facilitate installation.

In the debate between OEM and aftermarket suspension parts, it’s essential to understand the differing needs of manufacturers, shops, technicians, and consumers. OEMs prioritize standardization, while aftermarket providers focus on engineered solutions and longevity.

With suspension components, the topic can be framed as what are the needs of the OEM and what are the needs of the shop, technician and consumer.