Oil changes might not be the most lucrative service offered by your shop, but they are valuable to your customers. But, you should also realize that they can be a potential source of liability for the business. Mistakes happen to the best of us, and, in my experience, oil changes are a common place for mistakes or oversights to occur.

But the solution is simple – all you need to do is take your time. Think through the job, use the correct oil, filter and tools, and make sure you’re doing things in the right order.

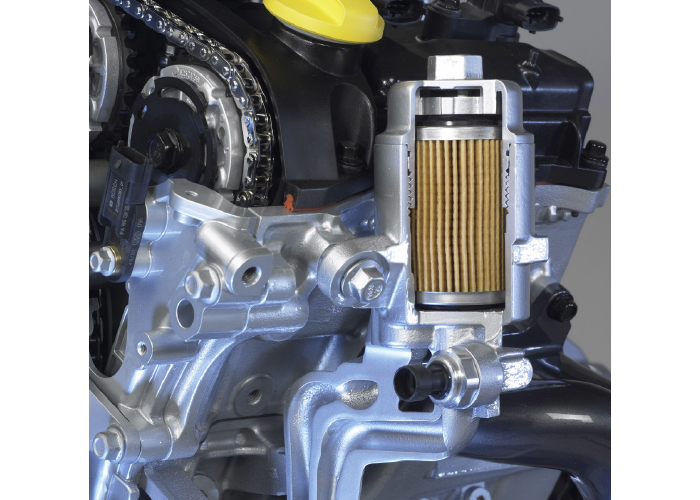

Cartridge Oil Filters

The unique construction of cartridge oil filters offers certain advantages over spin on filters, and they also present a few unique challenges.

Let’s look at their advantages first. In most cases, a cartridge filter will be mounted in an upright position. If this is the case, then the filter can usually be opened and inspected without draining the engine oil. This gives you an easy way to check for contamination, debris, or other engine oil concerns. They’re also more environmentally friendly thanks to their ease of recycling and/or disposal when compared to spin on filters.

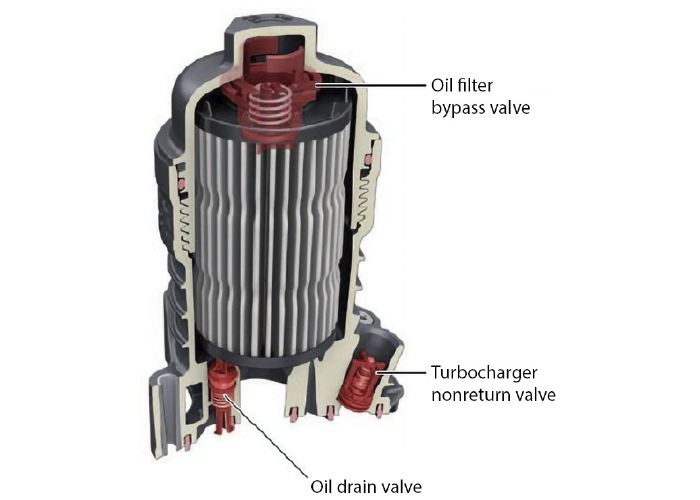

Bypass Valves

The main enemy of any filter is pressure differential. When a filter becomes clogged, the pressure outside the filter media becomes much higher than on the inside of the filter media. This is called a pressure differential. If the pressure differential is high enough, it can collapse and tear filter media. A high enough pressure differential can collapse a metal center tube long before an oil filter canister can burst. For some cartridge filters, you may notice an hourglass shape that indicates either the filter is clogged, or a heavier-than-recommended oil viscosity was used.

That’s where the bypass valve comes in. The bypass valve allows oil to bypass the filter if it is obstructed or clogged, preventing excessive pressure differentials which can damage the filters. The bypass valve can help, but when it is open, the oil is no longer being filtered.

Bypass valves can differ in design depending on the application or filter manufacturer. The valve can be as simple as a spring at the top of the filter or even integrated into the engine block or filter housing. A cartridge oil filter will typically have a bypass valve built into the oil filter housing or assembly, while others may have replaceable bypass valves. If you see any piece of plastic or the filter does not clip in or seat evenly, replace the cap, bypass valve or maybe the housing.

Nonreturn Valves

A nonreturn or anti-drainback valve prevents oil from draining or siphoning back into the oil pan. In some applications, the nonreturn valve prevents the oil level in valvetrain components and/or the turbocharger from dropping when the engine is shut off. This can help to prevent dry starts, bearing damage, as well as other long-term issues.

When spin-on filters were more common, technicians tended to drain the oil from the oil pan, then change the filter. But, today, with cartridge oil filters becoming more and more common, the rules have changed a bit.

For variable valve timing actuators, if the oil drains out of the chambers, it can cause a clunk or knocking noise when the engine starts. In some cases, the pin that locks the actuator can eventually shear off.

Oil Drain Valves

Most cartridge oil filters that are on top of the engine will use an oil drain valve (also known as an anti-drain back valve.) When the filter is removed, the oil inside the housing drains down into the pan. This oil is typically the dirtiest in the engine and needs to be drained from the engine. Also, the excess oil can cause the engine to be overfilled when new oil is poured into the engine. This is why it’s so important to either remove or loosen the oil filter housing so that the oil drain valve allows the oil inside the housing to drain down into the pan before you remove the drain plug.

Service Tips

Cleanliness comes first, so take the time to clean the cap and the filter housing during service. Roll the new O-rings into place; don’t pull, pry, or stretch them. Lightly lubricate them with clean engine oil, and be sure to align them with the threads in the housing before you start to tighten it down. The soft plastic on the cap can easily crack if you accidentally cross-thread it.

Always use the right tools. Just because a housing has wrench flats doesn’t mean you can use a conventional wrench, socket or even pliers to remove it. Tool suppliers have a wide selection of cartridge oil filter tools that will pay for themselves by preventing such a problem. Believe us, a cracked filter cap can quickly make a mess in the engine bay. It’s not worth the risk, or the damage you could cause to your shop’s reputation.

And, finally, look up the specifications and OEM service information. Many filter housing caps will have the torque spec stamped right on top of it. Torquing the cap to spec should help to prevent any risk of it cracking and making a huge mess.