Cheryl and Wayne Peaslee say their business exists for and because of their community, their team and their suppliers. At CW Repair Inc., an Auto Value Certified Service Center in Pittston, ME, “Service is the difference” and empathy is key.

“I remember one customer who told me, ‘I come back to you because you treat me like I’m a person. Not just as a number, not just as a black pickup,’” says Cheryl Peaslee. “I remember that so distinctly, because he was amazed that we could talk to him and get our work done. Of course, it’s true: we still answer the phone, we still carry on conversations and we get our work done. But, at the same time, we are including them in a conversation. To me that’s important: in this day and age everything is focused on technology. Sitting and talking to people has its advantages.”

The Peaslees says they’ve had an amazing relationship with Carparts (a division of Hahn Automotive), their Auto Value parts supplier, since the shop’s beginning in the early 1970s.

“At the very beginning, even when we were short on money, Carparts was a great partner. They were always there for us and we’ve stuck with them,” says Wayne. “I’ve been able to buy everything we need for the shop as well as parts for repairs, and there are never warranty issues.”

Cheryl says she appreciates the fact that her parts orders always receive priority treatment. “The team members at Carparts are great partners!”

In 1972, following graduation from high school, Wayne Peaslee started on his automotive career at a local Ford dealership in nearby Augusta. “I started out there on the lube rack. After almost two years, I decided to go out on my own.”

At age 19, Peaslee opened his own repair shop in his garage, eventually supplementing that business with a full-time job building warships at Bath Iron Works, the largest employer in the state.

“Somewhere in the mid-‘90s,” Wayne says, “we incorporated the business as CW Repair Inc.” And, Cheryl interjects, “In 2001, I gave him the ultimatum: I was running the business, when he’d go to BIW, second shift. I told him, ‘Either you stay home and run the business full time with me, or I’m done.’”

Peaslee says he recognized the writing on the wall and made customer service his number one priority. After two years of working out of their home garage, Cheryl and Wayne opened a new 3,200 sq. ft. facility on Pittston’s main drag.

The building consists of a 40×60 ft. shop, and a 40×20 ft. main office. “We recently added another 20×40 ft. open bay on the end of the shop with a portable Rotary lift capable of picking up 72,000 lbs. Now we can work on trucks, motor homes and other heavy equipment without limiting our ability to do automotive service,” Wayne says.

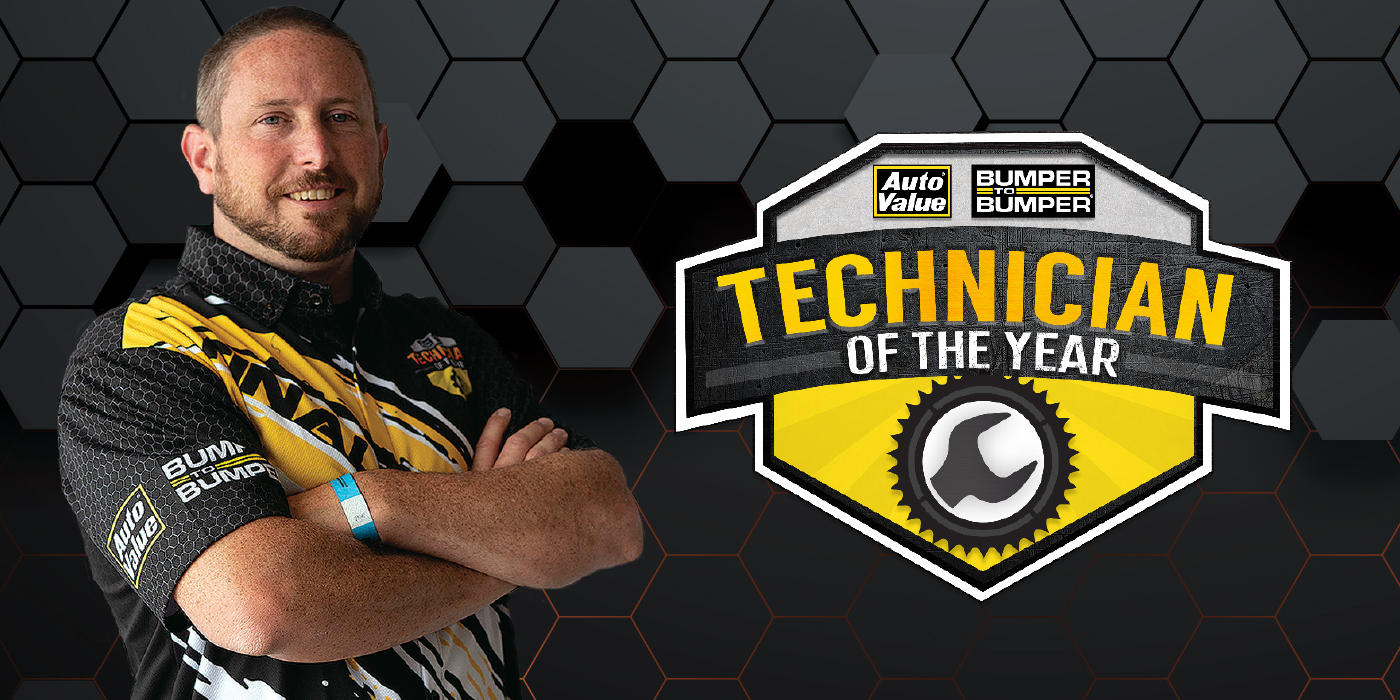

He and his team of two other technicians are proficient with today’s most challenging and complicated vehicle management systems. “We do just about every type of repair, for nearly every type of vehicle. I’m especially active with diagnosing and repairing electrical issues,” Wayne adds.

His skill in electrical diagnosis has made CW Repair the expert location for such service, from customers and other shops alike.

“He’s the go-to man in the area,” says Cheryl. “Other shops in the area send their electrical challenges down to us constantly.”

Wayne says his electrical abilities are, to an extent, hereditary. “My father had electrical training in the Army Signal Corps and when he got out of the Army, he continued his education. He used to repair all the black and white TVs in the area, and we had build-your-own radio kits all around, so I got my electrical skills from him. When I started working on cars and realized they had electrical issues, I knew what to do.”

According to Wayne, the process is simple: “If I get one, I can read the schematic and figure it out. We look at how it was wired, we figure out what’s wrong and rewire it correctly.”

Wayne says he relies on a variety of sources, including print magazines and manuals as well as the most current digital resources to keep his and his techs’ abilities up to date. Training continues to be critical.

In addition to himself, Wayne says he has two other skilled technicians serving customers’ needs.

“I have my ASE Master certifications, and while Terry Armstong and Matt Meck, my other two technicians, aren’t completely certified, we’ll fully support them when they complete the testing procedures.”

While Wayne’s in the back, Cheryl manages the business from the front of the shop. “I handle all the financial and employee issues; all that fun stuff that goes on behind the scenes. In addition, we take care of the customers – and that’s a huge responsibility,” she says.

“You have to be very friendly and outgoing, be able to handle a customer who is in a dispute with you. It’s important to understand the business, making sure you can provide a proper estimate, because that’s [the] foundation. If those estimates need to be adjusted, we must keep the customer involved,” she explains. “Along with Jaimy Snow, my service advisor, we need to be able to make those phone calls, do sales over the phone or even in-person. And, just as in the back of the shop, it’s the training piece that takes time.”

The Peaslees say they’re fortunate to have a great staff, but they’re always looking for new members of their team. “Finding the right person who also wants to be a valuable piece of the puzzle is key,” says Cheryl. “We pay well, we have a full benefits package, we try not to work any overtime at all possible. And that’s very attractive to a lot of younger techs.”

CW Repair is open from Monday to Friday – if it’s necessary to complete a job on the weekend the team will pull together, but typically customers are understanding. Other professionals, on the other hand, have more questions.

“I’ve had shops ask, ‘How are you able to do that?’” says Cheryl. “Well, if you’re doing your billable hours correctly on your estimates you don’t have to work weekends to make up that extra income.”

Cheryl admits that she and Wayne didn’t always think this way, until a training session provided by the Aftermarket Auto Parts Alliance Inc., during its annual convention more than 10 years ago gave her valuable information. “I was just a sponge and I brought home all the information and started applying it. Jaimy and I got together and said, ‘Okay, how are we going to make this company grow?’ We were suffering financially, so the first thing we did was to tell Wayne, ‘You can give no more estimates.’ You see, he would tell somebody a price for the parts…but the complete job includes labor and supplies as well,” she says.

What Cheryl learned from her Alliance training sessions allowed her to revise the shop’s method of pricing jobs. “Everything has to become profitable, not a loss. When we buy a new piece of equipment, are we charging enough for it to make it make a profit for us? Is it just the equipment or is there a labor and equipment charge that needs to be included? That’s been a key to our success, and Auto Value and the Alliance drove those things home. We’ve learned how not to be our own worst enemies.”

Shop training sessions are supplemented by general team conversations about all aspects of the shop’s operation, Cheryl says. “We really talk about things to have a good clue what’s going on. Nothing is kept secret from our employees. If any staff member has an issue, we try to implement whatever helps make their jobs easier. We try to empower our techs and show them that the best quality work brings back people time after time.”

In fact, it was an answer to his technicians’ requests that prompted Wayne to purchase the heavy-duty portable lifts. “We were getting into servicing heavier trucks and, frankly, it was hard on all of us. When we saw the lift in operation, we knew it was the answer to a prayer. Our techs love getting off their hands and knees. They’re able to work more comfortably and efficiently,” he says.

“Change is a good thing. We talk about shop bottlenecks very openly, how we can come up with solutions to implement so that we can quickly move beyond them.”

This collaboration exists outside the shop, as well. Because CW Repair doesn’t have an alignment rack, Wayne has developed a reciprocal agreement with another shop to handle that aspect of service. “I have one shop in Augusta, that is the only place I’ll send my alignment work. They are great friends of ours, too. We work hand in hand.”

The Peaslees are proud of the positive relationship they’ve built with their parts delivery drivers. Communication, says Cheryl, is key. “Being good to them is good for all of us. Our parts guys tell us all the time about how easy we are to work with.”

If there’s one factor the Peaslees say is important to shop success, it’s this: “Be kind. To customers, employees and suppliers,” says Cheryl. “There’s enough negativity outside the shop. We always try to be positive.”

The Pittston community sees that kindness every year, through CW Repair’s annual food drive.

“Starting each October, we run a food drive right up until about Thanksgiving. It started when a local food bank came in here with their van for some service work,” says Cheryl. “During the course of our conversation, Jaimy and I realized they had a need – we were determined to find a way to help. We sent out postcards to every customer on our mailing list and, lo and behold, things started coming back in. I remember that first year: it seemed like such a lot of food to us. The food bank was thrilled that we were able to collect eight or 10 good-sized boxes of donations.”

From that initial experiment, things quickly evolved. “After about two years, we gave out a coupon. If a customer brought five or more items or donated cash, we would give a $10-off coupon for their next service work. It was popular, but many people refused to take it, and instead donated it back for someone else’s bill,” says Wayne.

“This thrilled our customers, that they could benefit from helping others in multiple ways,” recalls Cheryl. “Recently, a good friend, neighbor and customer’s house and business totally burnt down. Jaimy and I were key parts in a fundraiser which raised over $12,000. We are very proud that we can serve our community that way.”

The Peaslees say their efforts to maximize the benefits for their employees and customers will be even more concentrated over the coming years, especially as they anticipate the profitable future of CW Repair in the hands of the next generation.

“We’re focusing on our employees, with training and mentorship,“ says Cheryl, “We’ll do everything we can to set them up for continued success at this shop after we eventually retire. We try to treat our employees like they’re our kids, and we want them to succeed as much as we can.”

Success is never guaranteed, of course, but confidence is essential.

“Sometimes you are flying by the seat of your pants. And, you’ve just got to be able to roll with the changes,” says Cheryl. “It’s called ‘live and learn,’ for the benefit of your customers, employees and yourself.”