Part 1: The Part Arrives, Time to Investigate

Let’s start at the beginning of a part’s journey: the delivery. A part of your vehicle has failed–let’s say a fuel pump. After performing some research, you order the new pump, take it home, and open the box.

Only for you to notice that there are pieces missing, something has come loose, and there’s a significant hole on the underside of the box. In fact, it isn’t the right part at all.

While your first thought may be that this should trigger a warranty claim, you should return it to the point of purchase right away. They will be able to give you the proper part, which you should then visually inspect for the following

Before accepting the new part, make sure to perform the following steps: here are some things to do before you even accept the part:

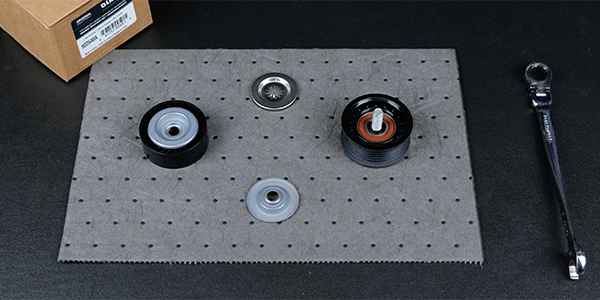

1. Confirm the brand on the box matches the brand of the part inside the box.

2. Always open the box and perform a visual inspection.

3. Make sure the box includes all the parts listed.

Remember, return the part, or refuse it if you notice any of the above. Submitting a warranty claim to the manufacturer should only be done if the part is installed and has failed prematurely, and is not due to circumstances such as contamination build up, incorrect installation, etc. Delphi provides a quick guide for fuel pump inspection guidelines, which you can find here.

Part 2: Regular Maintenance and Failures

After installing your part, it’s important to perform regular maintenance. This helps to ensure the part works optimally and meets or exceeds its intended lifespan.

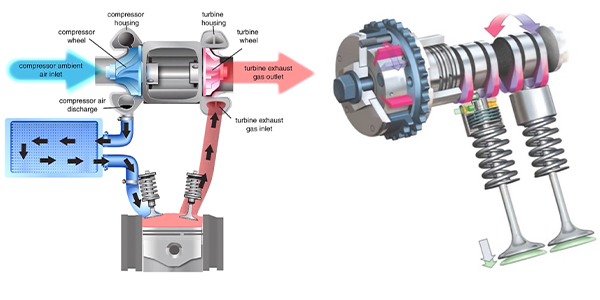

Something that should always be a part of regular maintenance is checking the air filter. Not only is it critical for the engine, but it also supplies air to a variety of other components, like the Mass Air Flow (MAF) Sensor. The MAF Sensor started appearing in vehicles in the mid-80’s and it measures the amount of air entering the engine to ensure a proper air/fuel ratio.

The air filter is the engine’s and MAF sensor’s first line of defense, protecting it from dirt, dust, and other debris. If the air filter is compromised, you may see a check engine light, poor fuel economy, excessive black smoke from the tailpipe and more. It’s recommended to perform a regular visual inspection of your air filter at least once a year (at each oil change would be optimal), or more often if driving on dirt roads. If the air filter is dirty, replace it to ensure the life of the engine and parts.

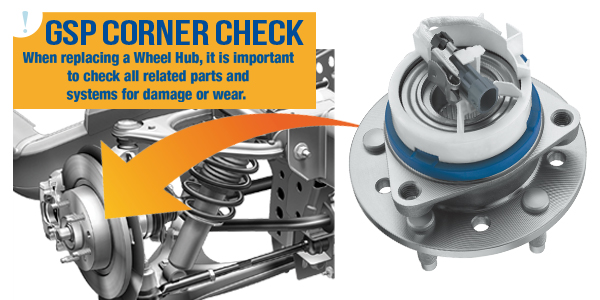

Let’s move on to another part—ball joints. Although they are designed to be highly durable, over time they will gradually wear, require replacing, and usually aren’t included in standard maintenance. Ideally, like the air filter, it should be checked regularly according to the owner’s manual.

But let’s say there are clunking noises coming from the vehicle’s front suspension when going over bumps or turning, as well as slight vehicle wander. After inspecting the chassis, it’s evident there’s a crack in the boot of the ball joint. Technicians and experts will often recommend in cases like these to not only replace the ball joint, but also the ball joint on the other side or both control arms.

In regard to the ball joint with the cracked boot, this is because water, salt, and other debris can enter the cracked boot and damage internal components. Strictly replacing the cracked boot with a new one has been shown to result in accelerated wear and corrosion.

As for replacing the ball joint without the damaged boot, it’s often recommended that for safety-critical parts they be replaced in pairs. This can be for a variety of reasons, such as compensating for the failing part, alignment, handling, potential control arm failure, and more.

Part 3: Turn to Delphi for Your Repairs

Now that it’s time to start the repair process, be sure to go with Delphi for all your part needs! With a presence in more than 150 countries, and a global network of over 2,750 service centers, Delphi provides OE specification end-to-end solutions from components to sophisticated software solutions that are also backed by OE-level diagnostic and test equipment, training, and technical information.

Delphi Fuel Pumps and Modules…

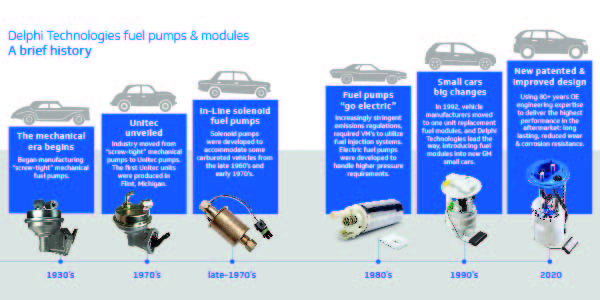

· Deliver dependable, OE fuel quality-backed manufacturing for almost 100 years

· Are a Tier 1 supplier to the top 25 global vehicle manufacturers

· Have 95% sales coverage from vintage to present models

· Have over 30 OE-proprietary innovations and 150 patents in fuel technologies

Delphi MAF Sensors….

· Are tested and calibrated to OE standards using highly precise OE equipment in Auburn Hills, Michigan.

· Are subjected to standard flow testing at extreme temperatures from -30°C to 80°C

· Are always new, never remanufactured

· Have a complete, full coverage program for Asian, Domestic, and European vehicles

Delphi Ball Joints…

· Undergo rigorous performance tests including angular stress testing, where the ball is rotated through its angular and rotational travel under load, as well as a pull and push out test, to measure the force required for it to break away from the housing.

· Have high strength, smooth operation, high-quality forgings

· Are extreme tested to meet or exceed OE standards

· Are machined and finished to micron tolerances

Start your journey or learn more today at delphiaftermarket.com.

This Article is Sponsored By: Delphi Technologies