With OBDI vehicles, the ECM calibrations were burned onto a computer chip called a PROM. The programming for the vehicle could be updated only with a new prom chip. Updating the ABS system (if equipped) or a system like an ADAS-related module was not even possible. As a result, many vehicles went to the junkyard with the same programming from the factory.

In 1988, engineers from all of the OEMs got together with the EPA and decided there had to be a better way to perform emissions testing and update a vehicle’s emissions software that may have fallen out of compliance.

In 1994, some of the first OBDII vehicles hit the roads with the 16-pin connector we know and love today. By the 1996 model year, all vehicles sold in the U.S. had to have it and the standardized protocols that would allow OEMs to update emission calibrations and firmware in the field.

When the OEMs got together to write the OBDII standards, the focus was not on the hardware like PROM chips; rather, the focus was on the software. They realized that a vehicle was not going to be driven back to the factory for reprogramming. Instead, it would have to be performed by skilled technicians. Thus, SAE J2534 was born to perform pass-thru programming in the field.

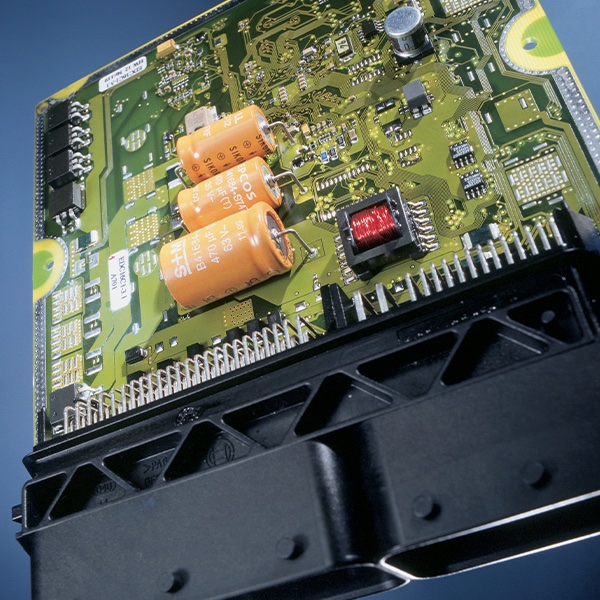

On all vehicles, the electronic hardware is nothing without software or firmware. There are over 100 million lines of code in a late-model vehicle, and even more if it’s equipped with an advanced ADAS system. This code tells the hardware when to shift an automatic transmission or if the recirc door in the HVAC system needs to be closed. Expecting the OEM to get every line of code perfect when it rolls out of the factory is an impossible task.

So, why would an OEM want to update the programming on a vehicle? It could be as simple as to reprogram a new parameter for an oxygen sensor or misfire monitor, so the check engine light does not come on during the 80,0000-mile emissions warranty. In other cases, it could be new software to take care of a glitch in the ABS.

J2534 flashing or reprogramming is a simple concept in theory. The procedure involves installing the most current software or firmware onto a vehicle’s module using the OBDII port. The software comes from an internet server owned by the OEM, which does not want you to have it on your hard drive. OEMs worldwide set up a system that allows the software or code to “pass-thru” your computer and onto the vehicle through a special interface.

As a vehicle ages, the J2534 programming becomes even more important. Why? When a new module or component is installed, the code or software from the OEM needs to be installed for the new part to function.

That is enough high-level discussion and theory for now. Following are the some important tools you need to start flashing or reprogramming at your shop.

Purchasing and setting up a PC can be the most challenging part of programming. Most OEMs require a Windows-based PC with specific hardware, operating system requirements and user settings. The computer should be used only for programming and navigating OEM websites.

You must have a stable Internet connection to flash or program modules on the vehicle. You can’t download a vehicle file at home and install it when you get to the shop. Never use WiFi.

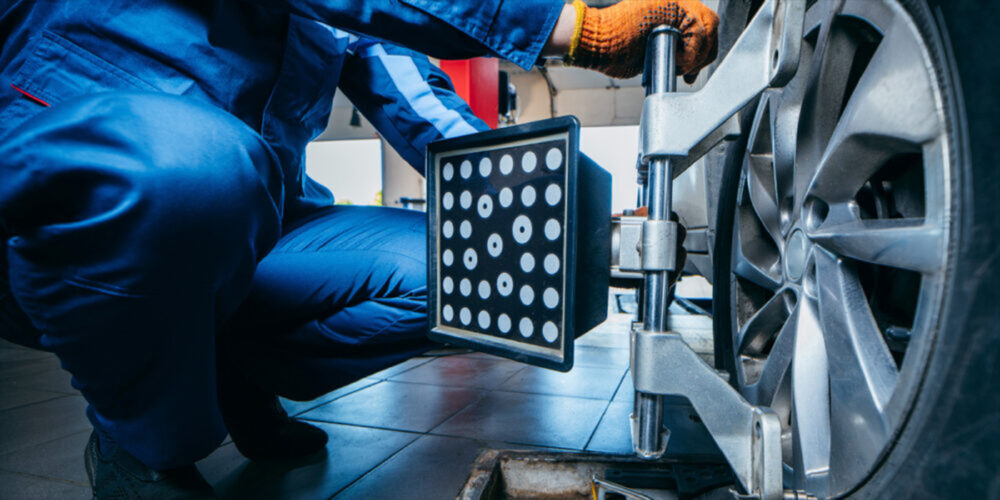

A J2534 pass-thru programmer is a box and/or cable with the ability to connect the PC to the vehicle and communicate with the correct pins on the OBDII connection. It is an interface that acts as a gateway that translates the messages back and forth between the PC and controller into a protocol that the vehicle understands. Many scan tool manufacturers make J2534 pass-thru programmers; just make sure the programmer is certified by the OEM you are planning to program.

Some programming sessions can last more than an hour and draw more than 80 amps to actuate components on the vehicle. Some vehicles will actuate ABS pumps, electric power steering motors and wipers as part of the reflash and calibration procedure. If the battery voltage drops below a set voltage, the flashing process will stop and possibly damage the module being programmed. There are power supplies made specifically for programming.

Your scan tool must be able to read Calibration Verification Numbers (CVN) and Mode $09 data. When an OEM issues an update, the new calibration number could be in a TSB. Always check for the latest version of the TSB. But, the latest calibration numbers will be listed on their service information website, so you will need to subscribe to the OEM’s service information website.

Flash reprogramming is not as intimidating as some articles and websites make it out to be. Just take your time and follow all the instructions.