Everybody who loves electricity raise your hand! What, no one? OK, everybody who loves cauliflower raise your hand! You know it’s bad when the second question gets a better response. But seriously, what is it with electricity?

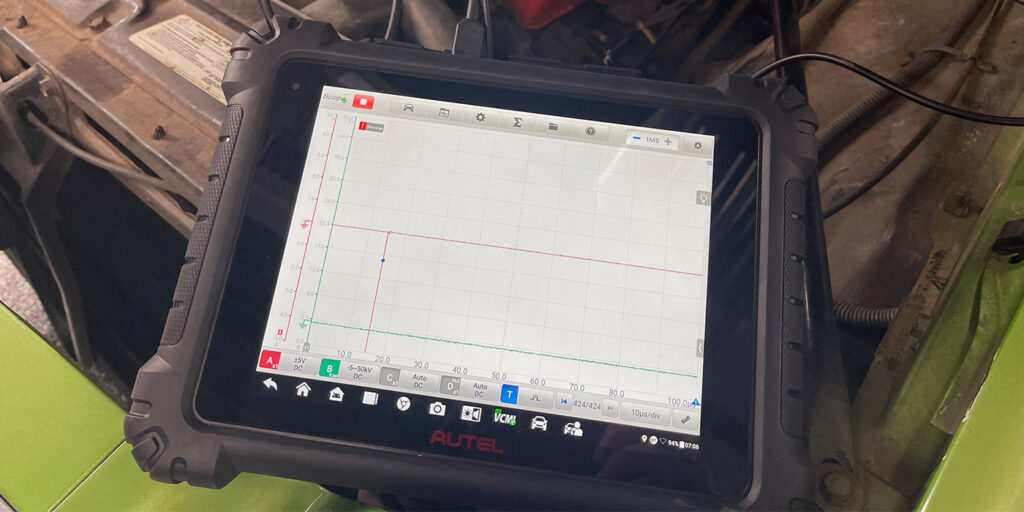

It’s a difficult subject, one that can be hard to understand and hard to explain, so it’s no surprise that it doesn’t get too much fanfare. As auto technicians, most of us get comfortable with voltage, resistance and amperage, both theoretically and in practice. Most of us all have our own digital multimeter and are comfortable utilizing most of the features. But mention oscilloscopes and the room clears, at least partly.

Those who remain will tell you it’s one of the most valuable diagnostic tools they have, and those who have mastered them make it look easy. When it comes to investing in an oscilloscope, from both the standpoint of a technician or a shop, the biggest question is return on investment (ROI). Is it going to make you money?

Oscilloscopes are tools that require regular use to take advantage of what they can do, and getting good with one can be compared to a video game. No one ever mastered Space Invaders the first time they played it, but it was fun, so instead of giving up, you fed endless quarters into it until you did. When you realize what they can do, oscilloscopes are fun too, and from a standpoint of diagnostics and ROI, it comes down to this: if you use one on a regular basis, it will prove invaluable. If it’s a dust collector, you wasted your money.

If you only use it on random occasions, you won’t be familiar enough with what it’s telling you to get the most out of it, and it’ll take too long to set it up. Even though they are far less complicated than they seem, if you don’t get used to all the settings and ranges, you’ll have to re-learn it every time. While this may only take minutes, this is time you don’t have when the process should be second nature.

You’ll need to develop a mindset that you’re going to “force” yourself to use it, even for an obvious problem. If you take a few minutes to hook it up and see what the readings look like for a problem, then compare them to the readings after the problem is fixed, you begin to build a knowledge base of reading an oscilloscope and a comfort level with using one.

Before getting into some examples, let’s touch on the basics of an oscilloscope. You’re familiar with a multimeter, also an invaluable tool, but think of a multimeter as a tool that gives you a static answer. What happens when you check voltage with a multimeter? It displays the answer in digits, but that’s it. If the voltage changes, the display will reflect it, but only at a relatively slow rate.

An oscilloscope will transform that voltage signal into a visual image in the form of a graph, and what’s better is it continues to display and graph the signal over time, so you can see indefinitely what happens with the electrical signal as it changes in response to what is happening in the circuit. In short, an oscilloscope displays voltage over time; a measurement referred to as a voltage waveform.

There are multiple different types of waveforms that can be displayed, and each one represents a different type of voltage signal, whether it oscillates, is an on/off signal, a pulse, voltage increase or decrease at steady or sudden rates or a combination of more than one.

An oscilloscope measures voltage and displays it visually as a graph in real time, the type of detail you can’t get with a multimeter. One of the factors that makes electricity difficult is that you can’t see it. An oscilloscope allows you to “see” the electrical signal.

What makes them so invaluable, in addition to their detail, are the attachments. You can get attachments for virtually anything you need to measure, such as pressure, amperage or temperature. What these attachments do is convert the actual reading into a low voltage signal that is sent to the oscilloscope.

To make it easier, so you don’t have to do any math or calculations, when the voltage reading is displayed, as long as you have set up the oscilloscope to know what attachment it is receiving the signal from, some oscilloscopes can convert the voltage reading to reflect the measurement you are looking for, such as pressure or temperature.

You’ve also certainly heard the term one, two, three or more channel scope. The channels are all the same. The more of them you have, the more you can do at once. You simply have to let the oscilloscope know which attachment is on which channel.

Now, let’s look at a more specific example of what they can do. Oscilloscopes first made their mark on automotive repair with ignition system diagnostics, and since we are all familiar with ignition systems, it is one of the best examples to demonstrate both their use and the diagnostic advantages they can have.

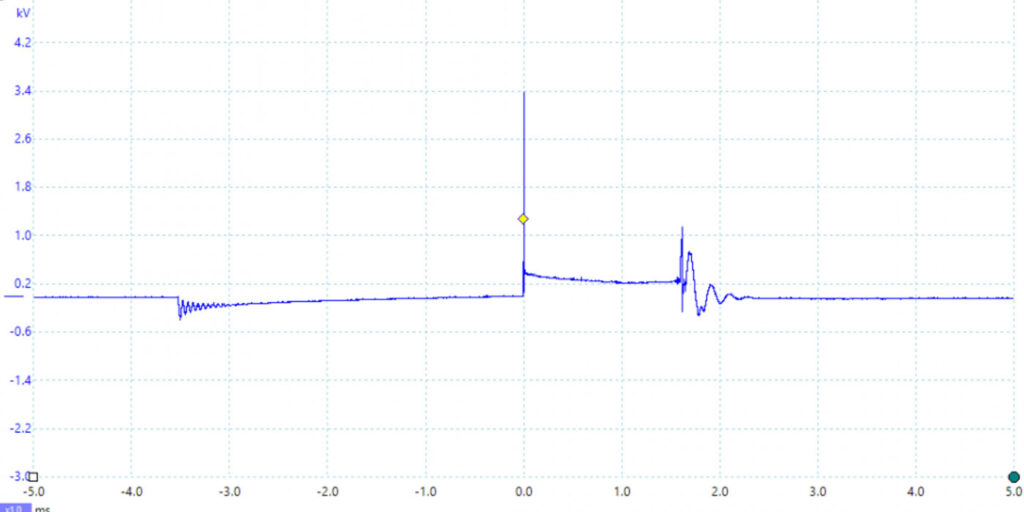

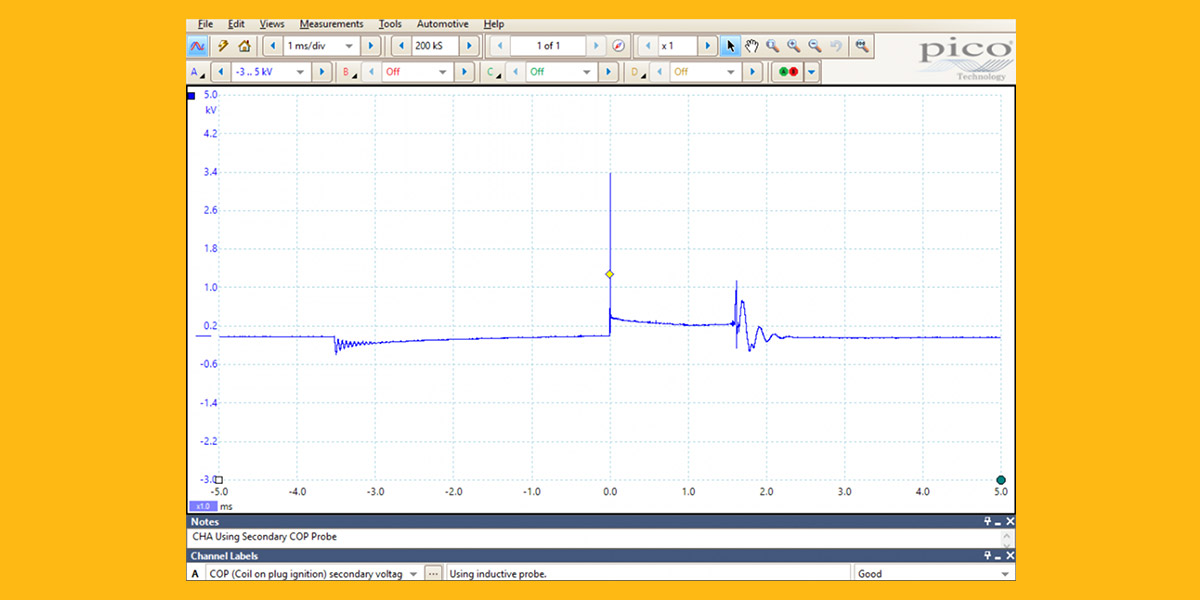

By looking at the ignition voltage and current waveforms, you can see exactly what is happening and in Figure 1, you see an example of a healthy ignition system. The first section is the dwell, which is the point of time during which current flows through the primary side of the coil building a strong magnetic field around the secondary windings. As the current begins to flow through the primary side of the coil and the resulting magnetic field begins to induce voltage in the secondary, coil oscillations are seen, which taper off as the coil becomes saturated.

The spike occurs at the point where the current flow through the primary side of the coil is interrupted, collapsing the magnetic field and inducing high voltage in the secondary side of the coil. The firing voltage is the high point of the spike, which is the minimum amount of electrical energy required for the spark to find the easiest path to ground. In the case of a healthy ignition system, it’s the initial point that the spark crosses the gap of the spark plug.

The actual firing voltage can vary between different ignition systems, and a variance between cylinders is normal due to the way an oscilloscope samples voltage, so don’t focus too much on a recurring variance. However, it’s the comparison between all the cylinders that is important, and a drastic variance in firing voltage can indicate a problem.

A lower voltage on one cylinder, for example, would indicate the voltage is finding an easier path to ground, such as a bad plug wire or low compression. A higher voltage on one cylinder would indicate a more difficult path to ground, for example, a spark plug gap that is too large.

This is a really good example of how regular use of a scope will build your familiarity with the waveforms and make it much easier for you to recognize when there is a problem.

The burn line is what you see after the spike, and it indicates both the amount of voltage required for the remaining energy to travel to ground and the burn time. Comparing this reading to other cylinders again helps you find a problem, and the voltage will be higher with a large spark plug gap or a lean condition. Again, the only way to maximize your familiarity of what the waveforms are telling you is to not only use a scope on a regular basis, but to also compare before-and-after readings.

The burn time is the duration of the spark, and it will be shorter with a large spark plug gap, a weak coil or a lean mixture. Finally, the ignition cycle ends with coil oscillations as the remaining energy that was not strong enough to push across the spark plug gap and thus absorbed by the coil.

A big advantage to using an oscilloscope for ignition diagnosis is we can spot a healthy ignition system. How many times has a car come in with misfire codes and you swap coils or even replace plugs hoping it will solve the problem? If there was no problem with the ignition system, a scope would have allowed you to eliminate the time and expense involved with guesswork and focus your time on the other possible causes of the problem.

A relative compression test measures the current draw required by the starter to crank the engine over, an efficient method to compare cylinders without removing spark plugs. This is extremely helpful, especially with a misfire present. While it can’t give you an actual compression pressure, if there’s a cylinder that is low (or high) compared to the others, you’ll spot it right away.

Another very useful test is a wiring test; one we all know commonly as the “wiggle” test. Many scopes offer a resistance probe that you can connect to both ends of the circuit, then as you wiggle the wire or harness, monitor the readings on the oscilloscope. You’ll see the pattern change if you locate a problem.

Oxygen sensors can be tested by connecting to the sensor signal circuit. ABS wheel speed sensors can be checked for signal accuracy. Crank and camshaft sensor waveforms can be checked as well as their relative positions.

Air flow sensors? An oscilloscope can evaluate the voltage output. Controller area network integrity? A scope can verify it. Battery and charging system testing? A scope can do it.

The common denominator is all the tests, aside from providing unmatched accuracy, simply require practice to get comfortable with. On top of it all, many oscilloscopes offer waveform libraries and analysis, so you always have assistance when you need it.

On today’s cars with today’s difficult diagnostics, an oscilloscope simply makes sense, and once you become proficient with it, it will translate to dollars. However, you have to use it, and you have to start sometime. There’s no better time than now.

This article appears courtesy of TechShop magazine.