“Everything changes, you know that. Nothing stays the same.”

If you jumped right on this quote, you’re a master of automotive movie trivia. If you’re not familiar with it, the line comes from Smitty in the 1980 movie Hollywood Knights. It’s set on Halloween night 1965 and you can bet it’s full of great cars, great music and great quotes, plus a number of well-known actors in their younger days.

This particular quote is one that stuck with me because it relates to anything in life, and the world of automotive diagnostics is no exception.

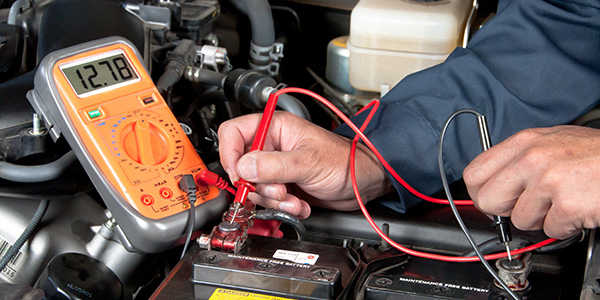

When we talk about battery, charging and starting system diagnostics, while it’s true there are certain aspects of it that have always been the same due to fundamental electronic principals, in the realm of tools, however, everything has changed. Electronics, along with charging and starting system technology, have advanced so dramatically over the last 20 years, that you must have modern equipment to keep up with it.

One of the most common diagnostic tools is a digital battery tester, and they’ve become affordable so many technicians choose to buy their own. They work by measuring battery conductance, which is ultimately a determination of the available plate surface inside a battery.

Sulfation is normal to a certain degree, but overcharging, storing with a low charge and storing at high temperatures can accelerate the process.

As a battery is used over time, two things happen in particular that are part of the normal “wear” of a battery. One, the plates become sulfated, meaning they have a buildup of lead sulfate crystals on the plates. Sulfation is normal to a certain degree, but overcharging, storing with a low charge and storing at high temperatures can accelerate the process. Two, the active material on the plates sheds off over time as part of the normal chemical discharge and charging process.

When either of these occur, the available plate surface inside the battery is reduced, and a digital battery tester takes into account the original battery rating, temperature, voltage and conductance to determine the overall condition. I’ve been using them for years with an interest in their accuracy, and I have no basis for any claim that they are not.

The reason digital battery testers are so important is they are quick and easy, and they are accurate even on a battery that is not fully charged. A weak battery can cause a lot of problems on a modern vehicle with multiple electronic control units. It’s important to identify battery trouble long before a vehicle won’t start or begins to set low voltage trouble codes.

Every time a car is in your bay, a digital battery tester makes it easy to check the battery. Not only is it important to your customer, but it’s a good upsell for you. If you don’t catch it, someone else will. Don’t let battery sales walk out the door.

All that being said, a traditional battery load tester is still very important to have. I never doubt the results of my digital battery tester, but if there’s a starting or charging concern and it indicates anything less than a perfect battery, you have to remember that these tools are assessing based on logic, and we know sometimes in this field you can throw logic out the window. If there’s any question about battery condition, a traditional load tester will give you absolute results. A weak battery has no way to hide from a load tester.

Modern load testers are a far cry from what they were years ago (think VAT-28 for those who like a trip down memory lane). Today’s testers are easy to hook up and feature digital displays, inductive amp clamps and a higher degree of accuracy.

When diagnosing starting and charging systems, an important detail not to overlook is performing a voltage drop test on the battery, starter and alternator cables. It’s safe to say that higher than normal resistance is responsible for the good majority of misdiagnosis and comebacks. A traditional load tester can be utilized to help you perform these tests.

An amp probe connected to a multimeter or the one on a load tester will provide amperage readings for starter and alternator performance, but for charging systems diagnosis, the real impetus is a scan tool. Modern charging systems are no longer stand-alone systems, with the vehicle ECM playing a large part in their control and operation.

A power management system is a more accurate name than charging system, and it includes the alternator, battery and ECM. These systems have been developed to improve fuel economy, battery life and alternator operation, and not only do they monitor battery condition, but some systems can estimate battery condition as well, using similar principals as a digital battery tester. They control and adjust charging output and they can also perform diagnostics and set diagnostic trouble codes.

When diagnosing a modern charging system, retrieving scan tool data from the power management system is part of the process. This adds a scan tool to the list of modern equipment that is required — and you’ll need a source for vehicle-specific information. We need a lot more equipment than we once did, and I might never have guessed we would, but as we know, everything changes. Nothing stays the same.