Many shop owners take the position that the best way to set their labor rate is to survey the competition, determine the top and bottom labor rate, and then set theirs in the middle. Conventional wisdom says that if I am not the highest or the lowest then the customer is more than likely going to choose the shop in the middle.

While this might be good for Goldilocks, it’s hardly an effective way to approach one of the most critical aspects of running a profitable shop. Setting your labor rate at the correct level keeps you profitable and allows you to draw exceptional talent.

Avoiding the deadly middle

Nordstrom, a leader in luxury retail, sets its prices for goods typically 25% higher than you can purchase from other retail outlets. The quality of the merchandise is exceptional, but it’s Nordstrom’s service that exceeds the expectations of even the pickiest customers and that comes at a price.

Wal-mart, whose former motto was “Always Low Prices” focuses on the value shopper. When you go there you know the quality might not be as high as other places; and neither will the level of service you will receive.

Each retailer occupies its respective space which, based on their business model, allows them to operate a profitable enterprise. While one caters to customers who appreciate quality and service ahead of price; the other draws the value-conscious buyer.

The space left in between is the area I call “the deadly middle,” where buyers are drawn to inexpensive or high quality. So, be careful when setting your labor rate as it compares to the rest of your market. Does your labor rate say “We’re not good enough to charge the most” or “Come to us because we’ll save you money?”

Quality Staff

Hiring and retaining quality staff is critical to a successful shop. While culture and identity are strong reasons employees work at your shop, compensation is what they put in the bank. Ensuring that your shop has a competitive labor rate will go a long way toward retaining top talent.

Examine your current pay plan

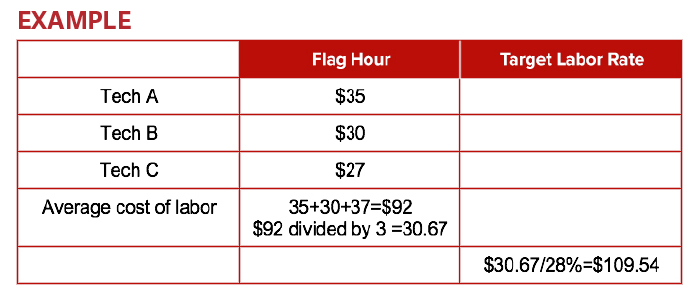

The industry benchmark for gross profit on labor is 72%. Your cost should be 28% of your collected labor dollars. The example in Chart A shows a sample shop with three technicians, using their rate of pay to determine what the shop’s labor rate should be based on the industry benchmark.

Know your competition

Performing a phone survey of the competition will help you to know where prices are trending. Be careful though – you should never discuss your labor rates and pricing with competitors. The federal government has strict laws against price-fixing as the consumer expects prices to be set independently and relevant to supply and demand. For more detailed and specific information, search the Federal Trade Commission’s website for “price fixing.”

It’s not just the labor rate

Along with having a competitive labor rate, there is an additional item to consider – utilizing a labor multiplier. The labor “guide” is just that, a guide that is meant to assist your shop in providing a fair estimate for the work required. There are many variables that are not taken into account in the published “guide” time.

Things Such as:

- Diagnosis;

- Rust;

- Extensive cleaning;

- Broken bolts;

- Deactivating and reactivating;

electronic systems; - Wheel locks; and

- Many other variables.

The key to evaluating your labor rate is to find the balance between charging a fair price that allows your shop to remain competitive, retain and draw customers and, at the same time, provide a wage to your employees that allows your shop to be highly profitable.

Reviewing these five points regularly will keep you on that path.