Do you just want to go through the motions of balancing wheels, or do you want to actually solve wheel vibration?

A shop owner has many choices when it comes to assessing which wheel balancer investment is best based on the size of the shop, skill level of its techs, its level of service and average number of wheel service-related repair orders, combined with planned growth potential in wheel balancing services.

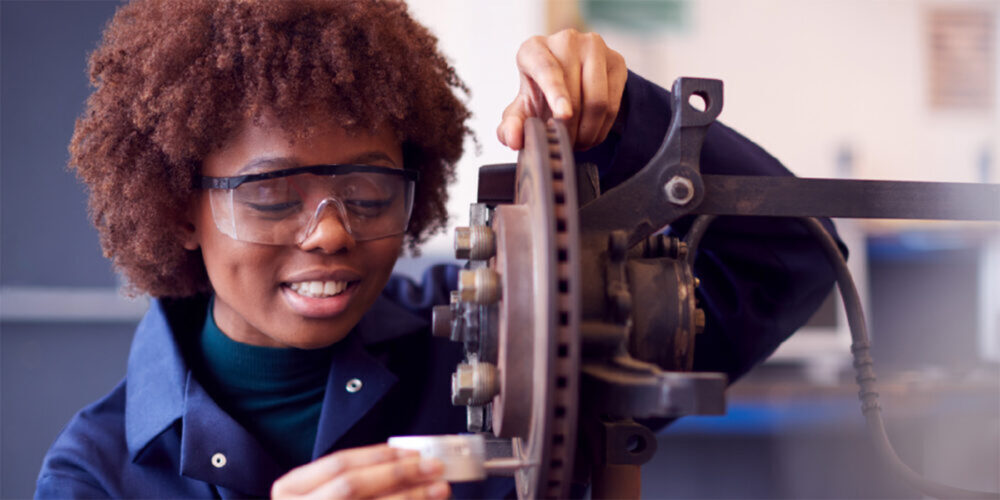

Wheels always need balancing when tire work is performed. However, this service can also be offered when rotations, alignment, suspension and brake work are needed as these repairs can also contribute to vibration and the onset of abnormal tire wear. Often, a road test and a small amount of customer education can go a long way to dramatically increase wheel balancing services to be sure the vehicle has a completely smooth ride quality.

Typical costs for wheel balancing can range anywhere from $8 to $25 per wheel ($32-$100 for all four wheels) but is typically about $10-$12 a wheel ($40-$48 total), depending on local labor rates and the make and model of the vehicle. Some shops even perform “patch balancing” with weighted balance pads on larger off-road truck wheels that require too many rim weights, to the tune of $60-$90 each. Considering that a balance can be performed in just a few minutes each, a premium wheel balancer can pay for itself in just a few months of use.

Wheel balancers come in many different types of configurations and performance capabilities. Features are based around efficiency, ease of use and how well the technician can balance the wheel, while protecting it from potential clamping damage to ensure the best possible ride quality and boost shop productivity and profitability.

Wheel balancers and their critical adaptor packages vary greatly in cost from about $900 – $18,000. The price range and corresponding differences in product features are huge. Your first consideration should be whether you just want to go through the motions of balancing wheels, or whether you want to do the best possible job solving wheel vibration.

There are different types of wheel balancers with a variety of features and benefits. This checklist can help determine which choice is best for you when searching for wheel balancing equipment for your shop.

Below is an example of the ROI a wheel balancer brings in for a shop that’s open six days per week.

Wheel Balancer Cost/Revenue Analysis Example

- Cost of Wheel Balance: $12

- Number per Day: 20

- Total Gross Revenue (per day): $240

- Gross Revenue Per Week: 1,440

- Gross Revenue Per Month: $5,760

- Gross Revenue per Year: $69,120

WHEEL BALANCER TYPES

- Traditional Balancer: Basic, low-volume, entry-level design

- Performance Balancer: Efficiency-based and high-volume design

- RFV Diagnostic Balancer: High-volume with RFV (eccentricity) measurement

TECHNICIAN INTERFACE

- LED Key Pad: A basic key pad entry and LED digital readout. Advanced features may be difficult to learn without training.

- LCD Monitor with Touch Key Pad: A monitor display with a key pad for entry, usually located below the monitor.

- LCD Monitor with Touch Screen: A touch-screen monitor should be used with a gloved hand; offers the simplest array of advanced feature accessibility and efficiency.

DRIVE SYSTEM

Input Voltage of 110v or 220v, 1Ph. 50/60Hz

Heavier assembly weights require higher motor torque. Heavier assemblies draw less electrical load with 220v motor drives. Motor drives come in AC or DC configurations, sometimes with servo capability used for toggling the wheel-to-weight placement positions.

WHEEL CLAMPING

- Standard or Quick-Clamping Wing Nut: The wing nut can be available in standard thread or a collapsible-jaw, quick-clamping design.

- Quick-Thread Servo Clamping: A standard wing nut can also be used with a servo motor drive to rotate the shaft to speed wheel clamping.

- Auto-Clamping Shaft: The balancer shaft will automatically retract and clamp the wheel when activated.

WHEEL LIFTS

Virtually all wheel balancers have horizontal-mounting shafts. Lifting heavy wheels to the balancer creates two potential problems (and opportunities) that can be solved with a wheel lift.

W Heavy wheels increase the potential for employee back strain and a wheel lift will protect the operator and make work easier.

W When heavy wheels are held into the clamping position with a wheel lift, it can increase centering accuracy and reduce the potential for a clamping error that can create incorrect balance measurements.

ADAPTORS

Centering cones and collets should fit the backside hub bore of most wheels that are to be balanced. Some alloy wheels are unable to be centered and can even be damaged unless the wheel is back cone-mounted.

Offset spacers are used to position some types of offset wheels so they fit on the balancer hub face and can be centered properly.

Clamp cups and sleeve protectors are basic pieces and allow the cones to be backside mounted.

Flange plates 4, 5, 6 and 8-lug PCD are highly recommended to allow the cones to be backside-mounted and protect the cosmetic side of the wheel face.

RIM DATA/WEIGHT LOCATION ENTRY CHOICES

- Manual Entry requires operator input of correct weight location in terms of distance, diameter and width between weight locations.

- 2-D (Distance and Diameter) allows inner data arm entry of distances and diameters required for adhesive tape-on weight balancing.

- 3-D (Distance, Diameter and Width) allows inner data arm entry of distances and diameters and outside wheel face of width measurement to the rim flange required for clip-weight balancing.

- Auto Data Entry and Weight Type selection may be automatically chosen without operator input of any type.

- Weight Positioning can be achieved by manual placement with the inner data arm, or the wheel may toggle and servo position to an automatic position and be easily positioned with a laser line or laser spotter at bottom dead center (BDC).

BALANCING

Calibration and calibration checks are not often required, however, an operator should be trained on how to perform these simple procedures if “weight chasing” during balancing is encountered.

Traditional Balancing Methodology addresses both static and couple forces with the same priorities for correction weight sensitivity. This is outdated and may cause weight chasing on adhesive tape-on weight balancing when distances are close to each other.

Single-Plane Dynamic Balancing software scans the wheel for a single weight placement location that allows for correction of both static and couple forces with one weight application, saving a significant amount of time and sometimes also reduces weight usage.

Auto Adaptive Compensation software determines the mass of the wheel and will adjust correction weight to best fit the vehicle sensitivity. It also allows shifting to a single weight and sometimes also reduces weight usage.

Static Force Elimination Balancing places priority on static balance correction weight over couple force correction reducing the traditional residual weight that can be left behind when a balancer shows “balanced.”

Hidden Weight/Behind-the-Spoke Balancing is a cosmetic split-weight function that allows the technician to hide adhesive weights behind wheel spokes.

RFV Diagnostic Balancing combines performance wheel balancing features with wheel eccentricity measurement to be sure the wheel is round when rolling when it’s balanced. Wheel radial runout can be measured with a roller, lasers or sonar sensor.

Most shops perform enough balancing services to achieve a tremendous return on investment when purchasing even the most high-end wheel balancers. Performance, accuracy, equipment capabilities and features, and training are critical to ensuring customer satisfaction and building repeat business.