In an industry where costs are increasing, the battle to keep costs or severity down is a tough one. It’s an interesting problem we all find ourselves in. Electronics and electronic procedures now are added to the severity issue, along with new metals and changing repair processes.

Issues of recommended versus required and who will or won’t pay for what have changed the landscape of our industry. The lack of a true understanding of why, what and how all these electronics work, as well as a lack of understanding how much liability is staring all of us in the face, has people not sleeping so well. How many of you, like myself, agree with that opinion? That is the beauty of our country. We’re all allowed to have our opinions. We have the right to express and value our own opinions. The problem is that many repair decisions are based on opinions versus following recommended or required procedures. That increases liability.

Reputation

Those who truly care about their work and take pride in it have a reputation of doing so…and that reputation is priceless. It increases the work in your shop and puts food on the table and shoes on the feet of your family. Your community trusts and respects your reputation. They use your shop based on that reputation. Other companies evaluating your shop as a service provider see that you’re doing it right and that you’ve made the necessary investments. They too value your reputation and wish to be associated with it. This builds trust and satisfaction for both parties.

It took you years to build that reputation. How fast can that reputation be destroyed? Our world is so different today than it was just five years ago. Internet, Facebook, Twitter and Snapchat have all made us so much more connected in a short time. One person can send out a review that will be seen by hundreds if not thousands of prospective customers. Perception becomes reality. Some people have made it a passion or even a business to rate someone else’s business. If they have an opinion that is negative, your reputation takes a hit.

Simple Expectations

In the auto body repair industry, most people have a pretty simple expectation on the repair of their vehicle. I dropped it off, and I expect it back fixed. They are mostly oblivious to what it takes and what must be done to repair their vehicle.

You may explain and they nod their head “yes,” the same way you nod “yes” if someone is explaining how to dry clean your clothes. You vaguely understand some things but really don’t understand it all or even want to, so you nod your head. We as an industry know what it takes, what is involved and how complex the repair may be. Most customers only want end results. Vehicle back, done. The rest is somebody else’s issue.

A good way to relate to this is to look at when a shop delivers the vehicle. When you do everything right and put the vehicle back to pre-accident condition, you can be proud of the steps you took. However, the customer arrives and sees that the vehicle still has dust in it or some overspray. Something that minor in the grand scale of the repair seems minor to the shop, but the vehicle owner has a different opinion. Your reputation just took a hit.

Trust But Validate

A vehicle that comes back to a shop because of problems it is having after a repair also damages a shop’s reputation. The question, “Why did these things happen?” or “Why didn’t the shop catch the issue?” is asked.

For years, many of us have taken for granted a good test drive. This often time-consuming but overlooked procedure could find problems before the customer found them driving home or to work. Alignments, noises, clunks and thunks could be found that weren’t there before. But a trip around the building or block does not constitute a test drive. You trust that your crew did the job perfectly. Now you need to verify it.

In our new world of electronics with vehicles reacting to sensor inputs to steer, stop or just basically take control in certain conditions, we as an industry need to verify that all systems are correctly working. This means the test drive has become that much more critical. It’s not just clearing codes and drive around the building; there are specific requirements OEMs have to verify the operation of safety systems in today’s vehicles. Not doing a proper test drive can lead to some bad reputation moments in today’s world that you cannot afford. It can also lead to serious liability.

A New World of Procedures

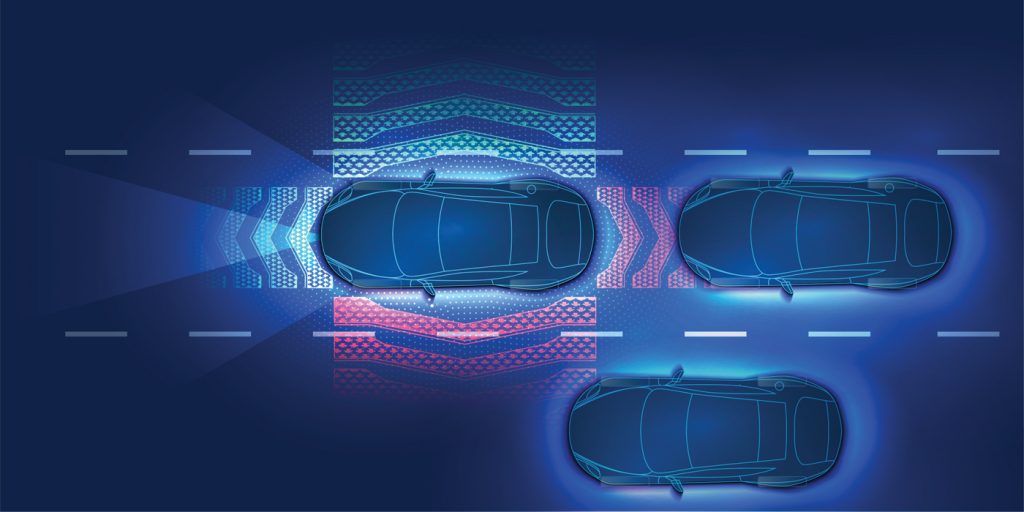

With the introduction of features in new vehicles that assist or take control of functions in specific events involving pedestrians or imminent collisions with other vehicles, we as an industry need to know what these systems are and how they work as well as repair and test all these new gizmos. Assistive driving systems such as lane keep warning or lane keep assist, automatic emergency breaking, adaptive cruise control, blind spot indicators and others have created a specialized repair section of the industry. Those who think it’s just plugging in a scan tool and the tool does the job are very misinformed.

There is so much more to even a pre-repair scan than just plugging in and reading codes. The same applies with a post-repair scan. A post-repair scan without a proper test drive followed by another scan or health check is only doing less than half the procedure. Plus, if you designate a person for the test drive who does not know how a system operates, let alone how to verify it is working correctly, you’re setting yourself up for problems. When that car comes back for a problem, remember that talk about reputation earlier?

What’s in a Test Drive?

So what’s in a test drive? That depends on the year, make and model of the vehicle. It also depends on what features are equipped in the vehicle. If you do not know what safety features are in the vehicle, estimating as well as repairing may be a challenge. Without that knowledge, the test drive will be difficult at best.

Different systems activate at different speeds. Some systems will need a specified minimum time at highway speeds. Vehicle modifications may also limit or prevent proper function such as modified wheels or lift kits. Every vehicle manufacturer will have a different procedure. One manufacturer requires driving the vehicle, stopping, turning the vehicle off, starting it back up and driving…and repeating this twice. It may take two cycles of the key to set a reoccurring DTC in the system. On the second cycle of the key, a self-initialization will occur and affect the ADAS components until complete. Some other considerations include:

- A full tank of gas may be required

- Highway speeds must be reached

- Start and stop procedures to verify brakes and suspension

- Cycle key a period of times and drive before final scan process

- Lines in the road

- Sunlight direction

- Signs on the roadway

- Drive cycle performed (different than a test drive)

- Specific distance traveled

- Scan tool may need to stay connected, requiring two technicians

Keep in mind this list will change all the time, but all will start with a post-repair scan to clear codes. A test drive will be performed and then another scan to check for reoccurring codes. A person who is unfamiliar with this technology or is not trained is not the person to do this procedure. If not done correctly, the customer may have issues and will have to return to find out what is wrong. This does not just verify electronics but all aspects of the repair, including mechanical and body structure. You as well as I know the end result on a comeback. No matter how well you handle the situation and problem, you’ve already put doubt in the customer’s mind as to the quality of the repair.

An interesting thing is that when repairs are completed, most settings are wiped out, especially on the advanced driver-assistance system (ADAS) components. This may be from a battery disconnect or recalibration of replaced or R&I’d components. The owner may not even know they’ve been driving around with the system off (or maybe on) since they purchased the vehicle. Now, the vehicle is behaving in an unfamiliar way, causing concern. If they’re driving, this panic becomes a shop’s worst nightmare. A panicked customer is rarely a good situation.

Set Expectations

Vehicle owners are not always sure how their vehicle works. They get used to whatever setting the vehicle is on and drive. When that setting changes, something must be wrong. Shops can alleviate much of this issue by preparing the owner for what must be done to repair their vehicles:

- Have a sign-off sheet when the vehicle is dropped, explaining that during repairs the battery may be disconnected and that recalibrations may be required. Since settings may not be saved, both of these procedures may require the owner to reset the ADAS settings to their liking. Instructions can be found in the owner’s manual.

- Your vehicle may require an extensive test drive. Some of these test drives may take up to 50 miles and up to two hours. If your vehicle is equipped with a GPS tracker connected to your electronic devices, you’ll see these test drives appear.

- Provide a map of the route, and be sure all employees stay on the route that will achieve all verifications.

Notifying a customer up front establishes confidence in your shop’s knowledge of repairs. This will also alleviate the panicking a vehicle might cause by not driving the “same” as before the repairs were done. Your reputation depends on delivering a vehicle right the first time. You have great techs and trust them. That is great. Remember to protect against liability by trusting but also verifying.

Mitch Becker has been a collision industry trainer for 30 years. He can be reached at (612) 865-6229 or [email protected].

Article courtesy of Body Shop Business.