When I think of turbocharged engines, the first thing that comes to mind is turbo lag. Turbo lag is the time it takes for the turbocharger, or turbochargers, to spool up and generate boost pressure after the throttle pedal has been pushed down. Looking back just a decade or two, turbo lag seemed to be much more common, and more severe. It seemed like you could put the pedal to the metal, count to five, check your watch, THEN you’d finally feel the boost kick in.

So, this begs the question: if turbocharged engines are so much more common today, what happened to turbo lag? It was solved thanks to years of development, and a bit of clever engineering.

It’s no secret that automakers have needed to get creative in order to meet emissions and fuel economy standards. These standards have presented a real challenge to automakers, and forced them to “think outside of the box.” Looking back on history, we’ve never shied away from a challenge. The atom bomb in World War II, the lunar landing to end the Space Race, the list goes on and on.

But in the case of solving turbo lag, I wouldn’t say that one particular advancement has simply ended the race in a single bound. Instead, it’s been a long haul with lots of players, all making a difference and moving toward the end solution. Let’s take a look at some of the ways that automakers have solved turbo lag in their modern engines.

Smaller Engines, Smarter Boost

Everywhere you look, it seems that engines have gotten smaller in displacement. Ford has its EcoBoost four cylinder and V6 engines, Nissan/Infiniti has the 3.0L VR engines, and Chevrolet has recently started offering a 2.7L turbo in the Silverado. These smaller displacement engines offer better fuel economy than the engines they’re replacing, but without turbocharging they wouldn’t be able to offer the same sort of power.

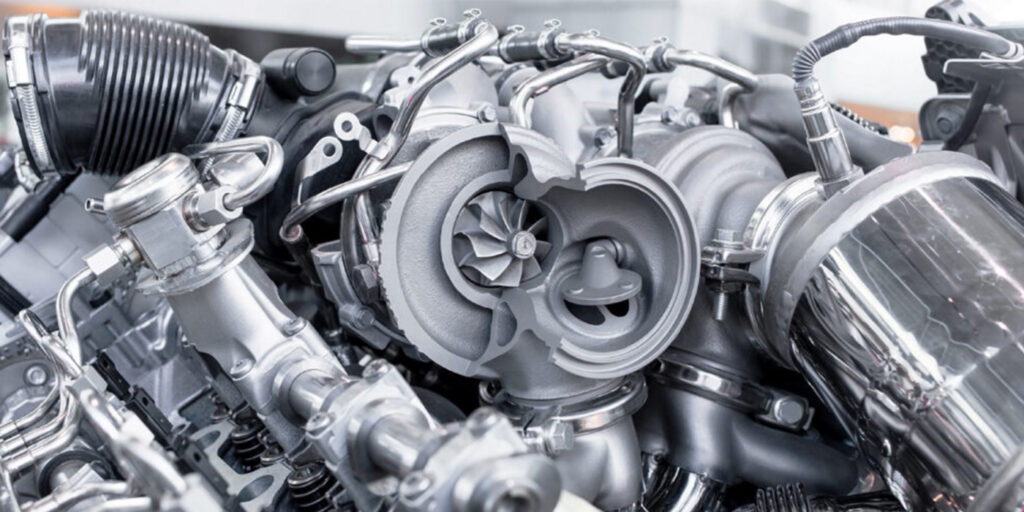

This is where smarter boost comes into play. Smaller displacement engines can use smaller turbos to fill in gaps in the powerband. Smaller turbos are able to spool up faster, leading to better response and more predictable power delivery. Modern turbos are also mounted closer to the engine than ever before. This means the exhaust gases don’t have to travel as far once they leave the combustion chamber, and the turbo can spool up faster.

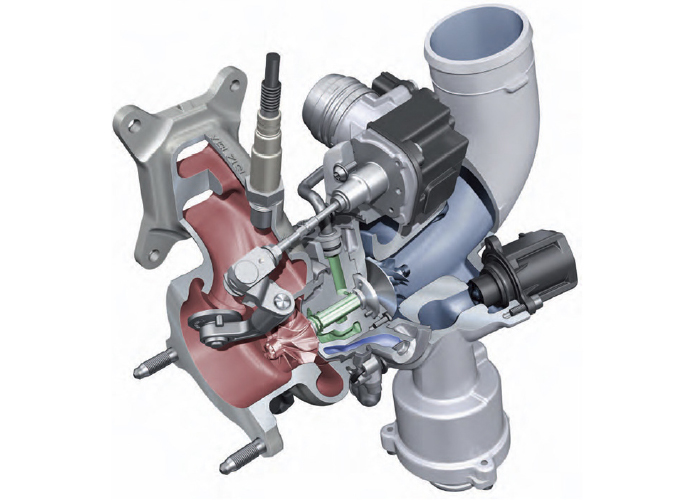

Let’s look at the 1.8T and 2.0T engines currently built by VW and Audi. These engines utilize a cylinder head design with an incorporated exhaust manifold. This means that the exhaust manifold is part of the cylinder head casting, and it is surrounded by cooling jackets. There are two main benefits to this design:

• When the engine is cold, the hot exhaust gases help to warm up the engine coolant. This means that the HVAC system can start heating the vehicle cabin much sooner, and the engine can reach operating temperature much faster, reducing harmful emissions.

• When the engine is at operating temperature, the engine coolant is able to reduce the exhaust gas temperature. This means that the engine control unit (ECU) can run a leaner air-to-fuel ratio, and maximize the catalyst temperature and performance.

It’s worth noting that VW and Audi are not the only automakers who have opted to use an integrated exhaust manifold design. Ford has used an integrated exhaust manifold on their 1.0L three cylinder EcoBoost engine, along with some of their four cylinder and V6 turbo engines. Honda used this design on the Civic Type R, Toyota (well, technically BMW) used it on the new Supra engine and the list goes on and on. There are other benefits to using an integrated manifold, including reduced weight, space savings and more.

Smarter Boost Control

Older wastegates and bypass valves were vacuum controlled, and were rather sluggish to respond to changes in driver input or driving conditions. Modern units are electronically controlled and allow for much more precise adjustments. Replacing vacuum control solenoids and diaphragms with fast-acting electronic actuators means that the ECU can be proactive with boost control, not reactive. The ECU can operate these two valves to reduce lag, keep the turbo spooled up and deliver power more consistently.

Variable valve timing (VVT) can be used to optimize turbo operation. Modern VVT systems offer more precise control than ever before, and allow for maximum control of the turbo in a number of driving conditions. The opening of the exhaust can be used to keep the turbo spooled up or to help scavenge exhaust gases from inside the cylinder. By adjusting the valve overlap, the ECU can also decrease pumping losses of the engine.

Twin Scroll Turbochargers

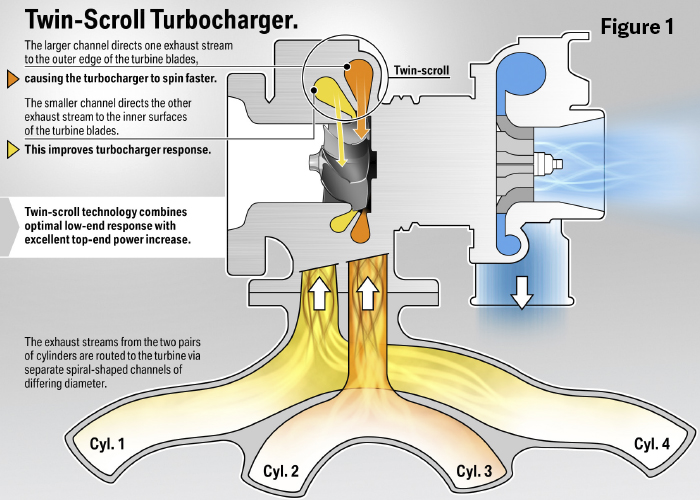

Automakers have looked to innovative technology to maximize turbo performance and response. One such example is the twin scroll design (Figure 1). Twin scroll turbos and exhaust manifolds contain two separate air channels inside. Since the air streams are separated, two cylinders are able to create a single stream of exhaust gases until it reaches the turbine.

Keeping these air channels separate helps to prevent the individual cylinders from interfering with one another, causing the turbine to slow down unintentionally. But the biggest advantage of a twin scroll turbo is the increased low-end torque. This is due in part to the separation of the air channels – and the fact that the exhaust gases are more evenly distributed across the turbine blades.

Hot-V Turbochargers

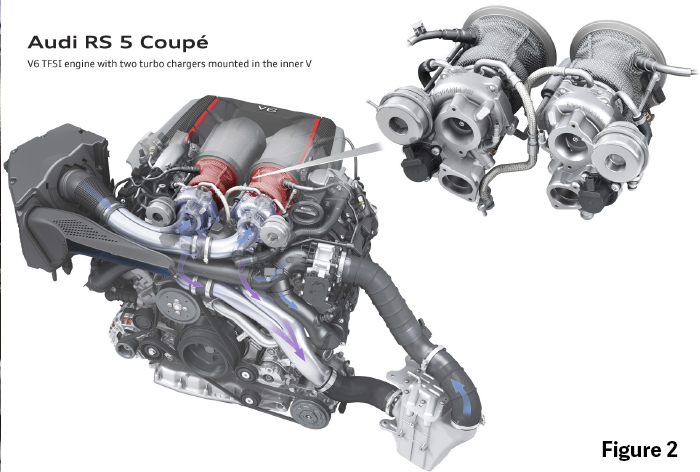

Let’s wrap up our list with one final method automakers have used to solve turbo lag: the “hot V.” In this type of engine setup, the intake manifolds are mounted on the outside of the cylinder head (where you might expect the exhaust manifolds to be), and the exhaust manifolds and turbo(s) are located inside the “V” of the engine (Figure 2).

This seemingly small change has a big impact on how the engine performs. The turbos are mounted extremely close to the cylinder heads, so the exhaust runners are very short. This maximizes turbo response and reduces lag. This also prevents excessive exhaust velocity loss, as well as heat loss through the manifold. Temperatures can be kept in check with some clever cooling solutions including dedicated coolant circuits, heat shields, air deflectors and more.

BMW, Audi and Mercedes-Benz have all incorporated this engine design into some of their lineups. Audi found a way to maximize the space inside the V by having each turbine rotate in opposite directions (Figure 3).

I know that EVs are coming, and that we need to think about moving away from fossil fuels, but I can’t help but marvel at the engineering from the past decade or two in the automotive space. Every time it has seemed like we’ve reached the pinnacle of performance, like we can’t squeeze another ounce of performance out of internal combustion, someone finds a way. This creative drive, this spirit of innovation, I believe is deeply rooted into us as a species.

Some of you may lament the oncoming wave of electrification, and I would tell you this: Just think what we can achieve with EVs if we put the same effort into developing that technology. I, for one, look forward to seeing what’s around the corner.