Ultrasonic cleaning is nothing new. Truthfully, the technology hasn’t changed much recently, but that doesn’t detract from the fact that it remains an excellent cleaning option for machine shops and engine builders looking for cleaning equipment.

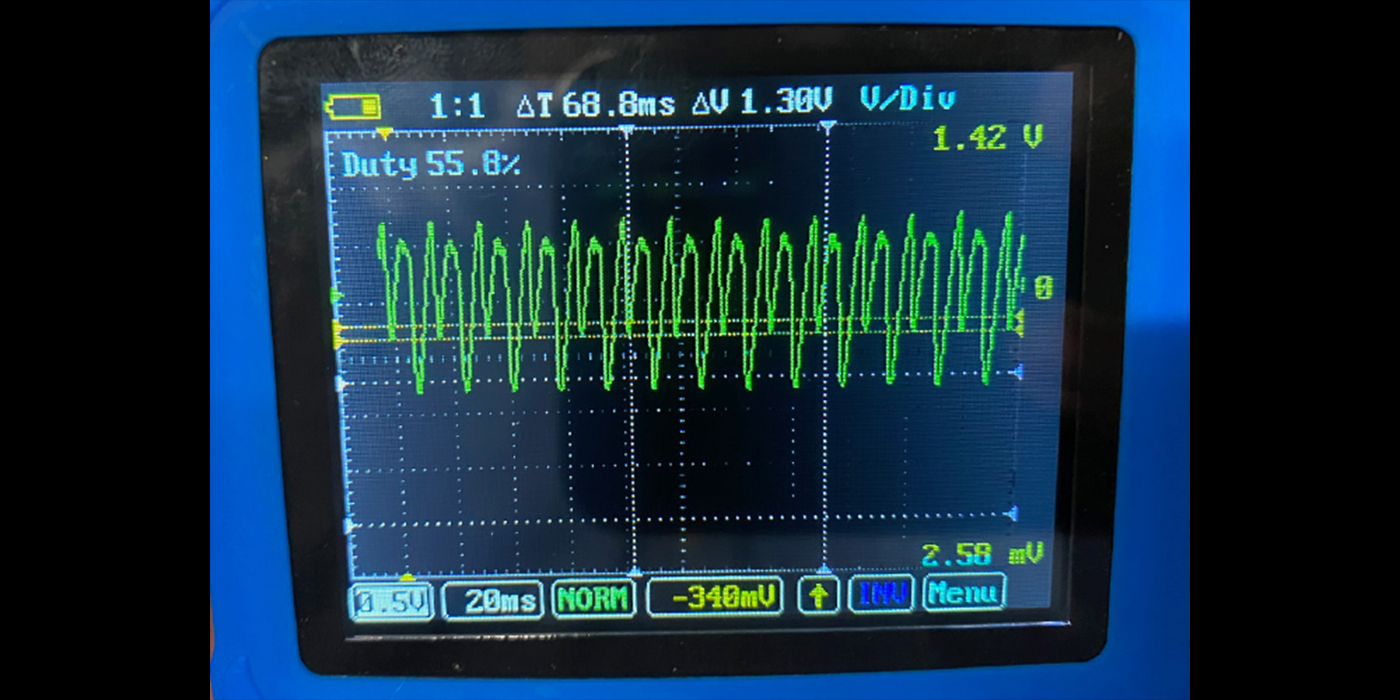

Ultrasonic cleaning is a process that uses ultrasound (usually from 20–40 kHz) to agitate a fluid. The ultrasound can be used with just water, but use of a solvent appropriate for the object to be cleaned and the type of soiling present enhances the effect. Cleaning normally lasts between three and six minutes, but can also exceed 20 minutes, depending on which object is being cleaned.

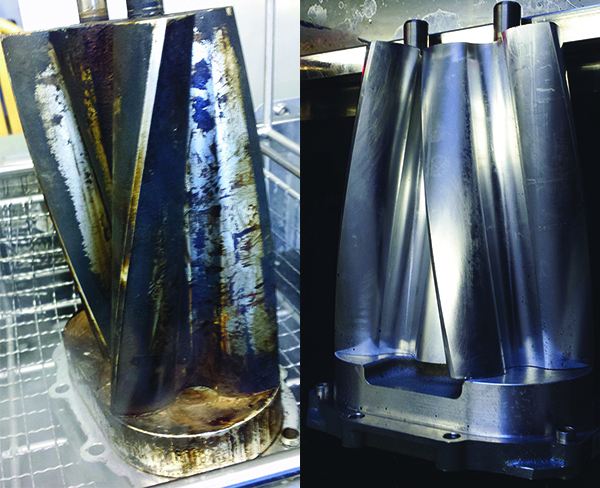

There’s virtually no limit to the type of objects ultrasonic cleaners can be used for, and that certainly rings true for engine components. Using cavitation bubbles induced by high frequency pressure (sound) waves to agitate a liquid, ultrasonic cleaning produces high forces on contaminants adhering to substrates like metals, plastics, glass, rubber, and ceramics.

This action also penetrates blind holes, cracks and recesses. The intention is to thoroughly remove all traces of contamination tightly adhering or embedded onto solid surfaces. Contaminants can include dust, dirt, oil, pigments, rust, grease, polishing compounds, fingerprints, soot, and much more.

The question many of you may have is why are they such a good option for the automotive industry? For many reasons.

“Ultrasonic cleaning has a ton of advantages,” says Jason Shaw, sales manager for Ultrasonic LLC. “Number one is time. Anybody who owns their own small business or races knows that time is money. That’s exactly what these machines are designed to do is save you time. Instead of standing in front of the parts tank for an hour cleaning a part, you drop it in this machine and you’re done in 5 or 10 minutes and you’re off doing something else. Your return on investment is extremely high.

“Number two is an environmental advantage. Everybody’s trying to get away from those harmful and nasty solvents and chemicals that are costly to buy, costly to dispose of and nobody has fun with their hands in a mineral spirits part tank all day long. Our machines use aqueous-based detergents. It’s basically just soap, water and three different detergents, but there’s no harmful chemicals and no harmful fumes. You can pour the soap directly down the drain. I’ve got my hands in it constantly and I still have all my digits. It’s much easier to dispose of and a much safer thing for employees and everyone to use.”

Speaking of the cleaning solutions used in ultrasonic equipment, the correct composition of the solution is very dependent upon the item being cleaned. As mentioned, Ultrasonic LLC largely uses aqueous solutions for engine parts, which contain detergents, wetting agents and other components, and have a large influence on the cleaning process. Solutions are mostly used warm, at about 120–150° F.

Water-based solutions are more limited in their ability to remove contaminants by chemical action alone than solvent solutions. The effort required to design an effective aqueous-cleaning system for a particular purpose is much greater than for a solvent system.

In aqueous cleaners, detergents are often added to permit dissolution of non-polar compounds such as oils and greases. An ultrasound generating transducer built into the chamber, or lowered into the fluid, produces ultrasonic waves in the fluid by changing size in concert with an electrical signal oscillating at ultrasonic frequency. This creates compression waves in the liquid of the tank, which leave behind many millions of microscopic bubbles (cavitation). These bubbles collapse with enormous energy, combined with temperature and pressure in order to clean and remove surface dirt and contaminants. The higher the frequency, the smaller the nodes between the cavitation points, which allows for cleaning of more intricate detail.

“What sets our machines apart from the rest is we have side-mounted transducers and agitation,” Shaw says. “What that means for the customer is a faster, more precise clean. Your traditional machines all have their transducers mounted on the bottom of the tank. All your sediment, dirt and sludge and whatnot that you’re cleaning off of whatever part it may be is naturally going to settle to the bottom of the tank. With your transducers down there, they have to fight through that and can stir those contaminants back up into the tank.

“What we did was we put transducers on the side of the tank and mixed it with agitation, which will move that part up and down and back and forth in the tank. It’s getting attacked from all different sides and angles and it helps flush the part as it’s cleaning it.”

The main advantage of an ultrasonic cleaner is going to be consistency. That precision clean is going to be delivered for a specific part the same way, every time.

“It is going to clean down into blind holes and places where you just can’t see, touch or feel,” he says. “It’s much more efficient than a parts washer and more economical to run. Within reason, pretty much all your parts can go in an ultrasonic cleaner. The main thing is watching what detergent or solvent or whatever chemical you’re using to clean with – especially in racing because everybody’s using a lot of billet.

“If you get too aggressive with your detergent or whatever it may be, it can discolor that aluminum and even etch it. If you’ve got a $50,000 billet motor, the last thing you want to do is turn it black and put little snowflakes all over it, so you have to be a little cautious there. That said, everything from pistons, connecting rods, timing covers, valve covers, plug wires, etc. can go in there. You’re more limited by the size of your tank and the cleaning solution you’re using.”

Depending on your shop’s cleaning set up, you may only need one ultrasonic machine, or you may require a few. It depends on the type of shop you have and your cleaning needs.

“We get it every year at PRI, somebody will come back and say, ‘I wish I bought the larger unit,’” Shaw says. “Every year we hear that. Some guys will run a tabletop for carburetors and nuts and bolts and whatnot, and then have a 3200 for engine blocks. There’s plenty of people out there who are using multiple machines. Having multiple units is not going to do anything but be advantageous to an engine shop.”

Aside from getting a nice, clean part after use, the real advantages of ultrasonic cleaning are seen in time and environmental impact.

“If you’re doing a head or a block before final assembly to just get some of those machining oils and a little bit of debris off of it, you’re looking at 3-5 minutes,” he says. “Compared to hand cleaning that and there being no guarantees you’ll get down into all the ports and the blind holes cleaned out, that’s your advantage with an ultrasonic cleaner. You can use them after media blasting and they could be used for initial cleaning as well. That will save you a ton of time at a parts tank.

“The environmental side of it is something that’s not mentioned enough. It’s something that’s a big thing for us because we’re trying to go green. Ultrasonics are just safer for everybody to use. The time savings and return on investment are major points. It’s what keeps us in business. These machines are made to help everyone from a mom and pop shop all the way up to your big racers make money. It’s a better way to clean. It’s a faster way to clean. You just can’t beat it.”

As a shop owner, you always have options when it comes to purchasing new equipment, and ultrasonic cleaners are one you may want to investigate.

This article first appeared in Engine Builder magazine.