Since the U.S. TPMS mandate took hold in 2007, independent repairers have spent time acquiring the knowledge and skills necessary to meet new TPMS service requirements only to find that the technology and implementation continues to evolve over time. This shift in methodology has left many repairers struggling to keep up with new repair procedures.

Traditionally, when servicing many Chrysler vehicles, technicians would benefit from the simplicity of its Auto-Learn relearn procedure. After successfully programming and installing replacement sensors, a short drive is required for the vehicle to localize the four wheels and display the pressures and wheel locations on the driver information center. How does it do this?

TPMS RF antennas are located near each wheel and tire assembly. There are 2 antennas in the front and one in the rear. The ignition switch module acts as the 4th antenna – accounting for all four wheels. During a test drive at sustained speeds over 15 mph, the accelerometers in the sensors will cause the sensors to activate and transmit the sensor ID and wheel location information to the controller. The equipment level and componentry required for this system to work correctly is complex and expensive to integrate, however it simplifies the relearn process for technicians.

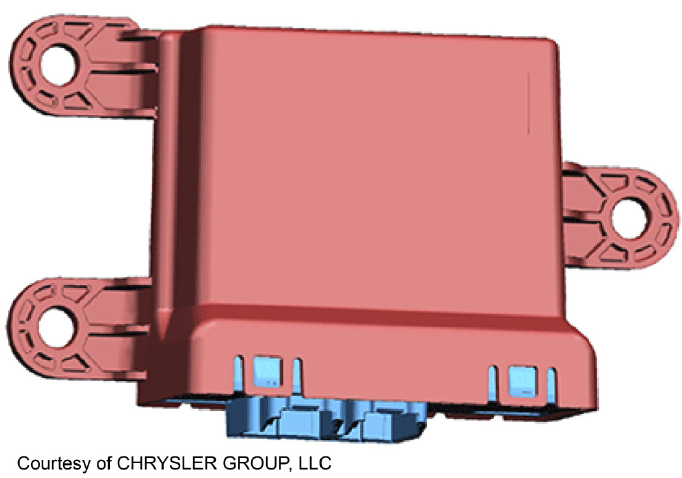

Since 2018, Fiat Chrysler Automobiles (FCA), along with other manufacturers, have been developing technologies to protect their vehicles’ networks from unauthorized access, including potential cyber-attacks. FCA recently implemented a Secure Gateway Module that was introduced on a selection of its 2018 and newer vehicles.

For vehicles with a Secure Gateway Module (SGM), access to certain diagnostic functions require registration and authentication through an approved device. This is true for all aftermarket scan tools that participate in the AutoAuth program. In some cases, special access can be required for TPMS service procedures that include changing the sensor ID configuration.

Early attempts to circumvent the SGM module required the utilization of a specialty bypass cable. This involved disassembly of interior sections of the vehicle to gain access to the physical SGM module and plugging the cable directly into the SGM controller. Removing components such as the infotainment screen or the footwell interior trim to gain access proved time consuming and impractical for simple service procedures, such as a TPMS relearn.

Due to the addition of the SGM module, when attempting to auto-learn an FCA vehicle where a new sensor has been added, technicians may sometimes have difficulty relearning new sensor IDs to the TPMS Control Module. Certain TPMS-equipped diagnostic tablets are equipped with access to AutoAuth software, a subscription-based 3rd party software service that will allow access to all vehicles systems including TPMS through the security feature.

It is important to note there is still access to output data, including code scanning, live data and freeze-frame data without special authorization. The limitation appears when a technician attempts bi-directional functions. Without access, we cannot operate any of the vehicle’s systems, execute component activation, or service bay tests on the vehicle.

Where does this fit in with TPMS? When adding or changing any of the vehicle’s TPMS Sensor IDs they are required to be learned to the vehicle. This is a bi-directional function that can be blocked by the SGM. A simple tire rotation or tire replacement is not problematic because the IDs remain the same, and all that changes are the wheel’s locations.

Autel’s Tech support is constantly fielding calls from technicians who are unable to successfully service SGM-equipped vehicles with universal programmable TPMS sensors. Armed with the knowledge of these systems, a subscription to AutoAuth and a capable TPMS and service tool eliminates the complications related to servicing these systems.

What if we are trying to get by with a more modest TPMS tool that is not capable of utilizing an AutoAuth subscription?

The most important consideration when servicing an SGM-equipped Chrysler vehicle is that regardless of how many sensors are being replaced, the sensor IDs should remain consistent with the factory equipment. To accomplish this, we must consider the sensor programming method we are using prior to sensor installation. Most TPMS tools will offer an “auto create” programming method that will assign the new sensor a random, but compatible, ID and the correct communication protocol for the vehicle. This method will prove ineffective as a new ID will not be accepted by the system. Instead, the recommendation is to stick to a cloning method.

These methods are available on most handheld TPMS tools – on Autel’s TS508 tool specifically, this can be accomplished in several ways. We can utilize the “Copy By OBD” programming method. A sensor is duplicated based on the information stored in the control module.

The tool will communicate with the vehicle via the diagnostic port and access the existing ID information from the controller. This will allow the replacement sensor to be programmed using the current sensor ID information. Cloning or “copy by activation,” as it is listed on the TS508, will allow technicians to activate the old sensor, if the sensor is still functioning, and extract the old ID information. We can then create a new sensor with the same ID information and characteristics.

Or, we can choose a “manual input” programming method if the sensor’s battery is dead or it is unable to activate. A manual input programming method will allow the technician to manually type the ID stamped on the original sensor into the TPMS tool and create a sensor with the same ID. These programming methods will maintain consistent ID information between the new and old sensors and eliminate the need to “teach” the vehicle new sensor IDs.

Although the sensors used in SGM-equipped systems are quite new and will not require replacement right away, there are some circumstances where we would be required to service the TPMS on these vehicles.

Winter tires, for example, are compulsory in certain Canadian provinces including Quebec and British Columbia. Many motorists may opt to store and maintain a pre-built set of wheels and tires with pre-installed TPMS sensors. Creating replicas of the existing sensor IDs is the easiest way to eliminate complications that come with swapping out the sets.

There may also be scenarios when a vehicle may sustain damage due to road hazards or collisions. It is never too early for tire installers to become familiar with these new technologies and service requirements. It is important to gain a thorough understanding of these new systems now so that we are fully prepared to meet our customers’ needs as demand for service increases among these models.

The aftermarket automotive tool industry’s primary goal is to stay ahead of the curve technologically and provide the next generation of solutions. Additional service capability will always translate to new revenue streams for repairers. Innovative industry tool manufacturers will continue to adapt to these changes, ensuring that our customers remain successful now and in the future.