Ben Johnson, director of product management for Mitchell 1, recently participated in a Frost & Sullivan webinar presentation titled, “Global Automotive Aftermarket: Strategies for Revenue Generation & Growth.” To view the recorded session, visit the BrightTALK website and fill out the free online registration form. Johnson’s presentation begins around the 45:00 mark.

Johnson joined host Anuj Monga, a senior research analyst for Frost & Sullivan’s Automotive & Transportation research practice. The webinar covered the impact of COVID-19 on the global automotive aftermarket, particularly looking at the reduced demand for replacement parts and accessories, as well as the longstanding implications of COVID on the evolution of the aftermarket by influencing market participants to refresh their approach to the market. They also spoke about the disruptions in in-vehicle technology, resultant opportunities from servicing electric and autonomous vehicles, and new business models, particularly for digitizing offering and fulfillment programs to be competitive in the independent aftermarket.

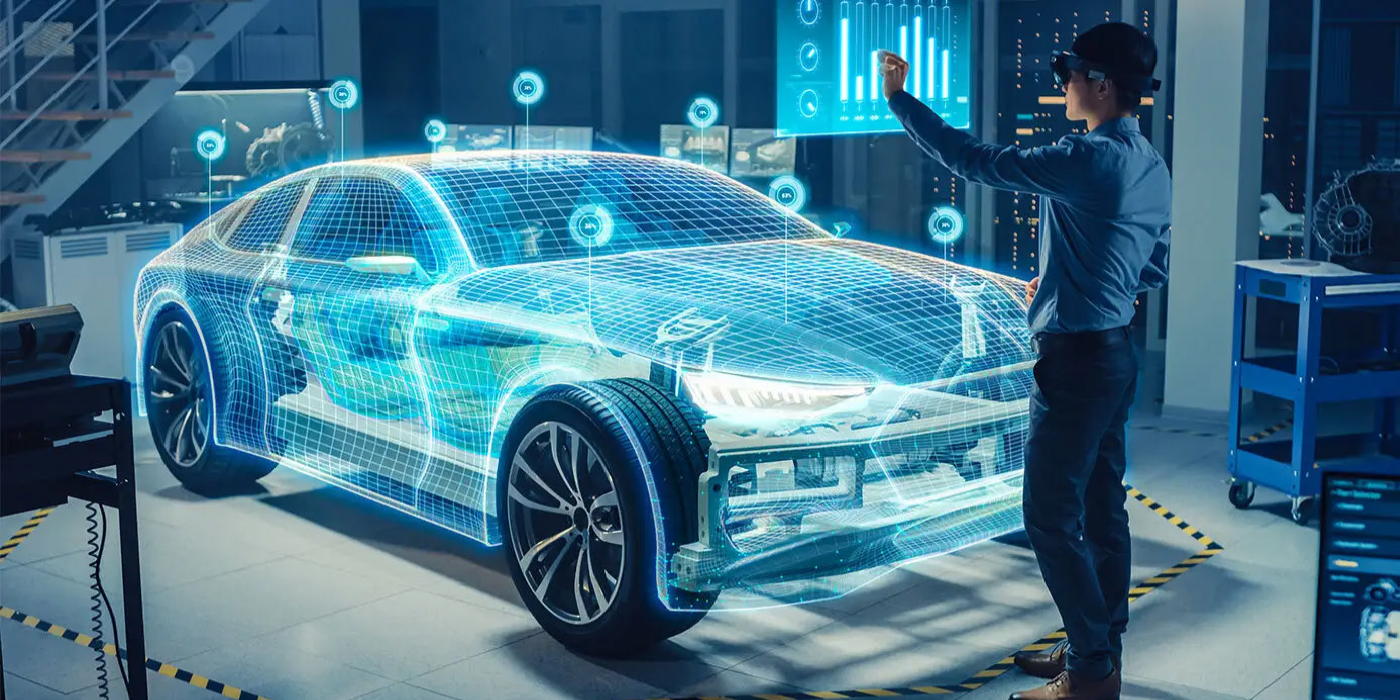

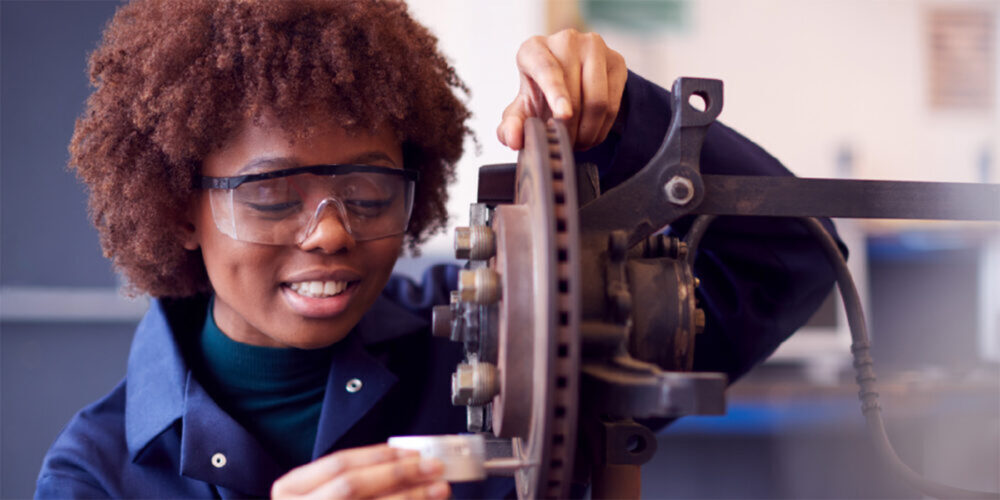

Johnson’s presentation offered insights about the ongoing efforts by vehicle manufacturers to further electrify vehicles and steps that repair facilities can be taking to prepare for the next waves of technology. While major impact from battery electric vehicles to the nationwide car parc is still several years away, Johnson reminded participants that enhanced systems like start-stop, electric HVAC and various ADAS components have been evolving for several years and are providing new opportunities for shops today.

“It was great to be part of this discussion,” said Johnson. “Because of Mitchell1’s leading market position, we are uniquely positioned to give a ‘feet on the street’ view of the impact of COVID-19 to our nation’s repair facilities. It is also very important to be involved in the ongoing discussion about the roadmap to electric vehicles. Shops need to realize and be prepared for the new technologies and opportunities they will present as they begin visiting their bays.”

Johnson is responsible for managing Mitchell 1’s portfolio of products for the motor vehicle industry. He maintains several ASE certifications and is a member of the Society of Automotive Engineers (SAE) International. He currently serves on the Auto Care Association’s Tool & Equipment and Emerging Technologies committees, the multi-association Telematics Task Force and the Automotive Aftermarket Suppliers Association (AASA) Telematics Working Group. He is a frequent presenter at industry events on the topic of ADAS and emerging automotive technologies.

Photo by Ramón Salinero on Unsplash