The relationship between collision and mechanical repair has, perhaps, never been more important. The body man can get the panels smooth and straight and the suspension guy can make sure the components aren’t worn and the wheels are aligned.

However, if the cameras aren’t perfectly calibrated, today’s ADAS-equipped cars will give their drivers nothing but nightmares.

Tom McGuire, COO of Precision Diagnostics in Madison, WI, has built a company that recognizes the importance of the synergy between all three factors in the equation.

“I had been in the collision industry almost 35 years, as an independent owner-operator,” says McGuire. “I grew up as a technician, and then worked for a couple of large national MSOs in different leadership capacities with them. When I left in 2019 to start Precision, we had found that one of the biggest pain points in the collision industry — which applies to mechanical shops and glass shops as well — was getting cars back from dealerships for typical ADAS calibrations.”

McGuire says the numbers were staggering. “We were leaving $100,000 a month between 10 shops on the curb because our collision couldn’t get a module programmed for even something as simple as an alignment.”

McGuire says the impetus for Precision Diagnostics was to create an “easy button” for the collision world. He took the things that were pain points for him in the industry and took them out of the equation.

“If we can do calibrations, if we can do programming, if we can do suspension-related work for collision shops it will help, because we knew that we want body techs in the world fixing sheet metal, not necessarily hanging engine cradles,” he says.

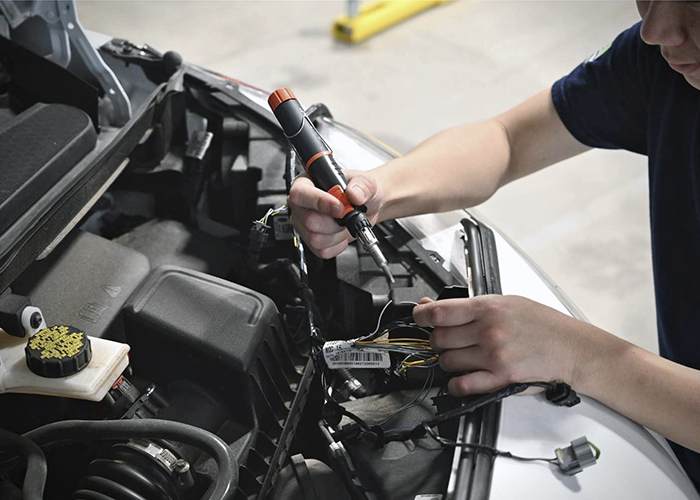

With a strictly business-to-business approach, the innovative business plan was formed. Simply put, it’s this: Precision Diagnostics performs OE diagnostics and calibrations using the latest OE tools and software and a wide assortment of aftermarket resources, including Autel and Hunter technology training. In addition, says McGuire, a “don’t lift a finger” attitude is part of the company’s DNA.

“We pick up, repair and deliver so our clients don’t have to lose focus on their core business,” explains McGuire. “Whether you’re a body shop, a mechanical operation or a glass installer needing calibrations, you literally are our priority. There is none of that noise that happens in the middle of it with retail.”

The company started in Madison, WI, in a 5,000-square-foot physical calibration center, in July 2019, says McGuire. “In February 2020, we opened our Pewaukee calibration center, which is about 8,500 square feet. We’ve got nine mobile vans running across Wisconsin. We went into Iowa in January of ’21, and now cover the entire state in a mobile fashion. We just launched St. Louis and we launch Omaha in July.”

McGuire admits that while the company’s growth trajectory has been phenomenal, there was legitimate concern it could have been stifled by Covid. However, he and his business partner, Dave Zielke, felt there was no turning back.

“We made a commitment to go either all the way in, or we weren’t going do it. It’s about being able to say ‘yes,’ and confidently know that I can make it happen, that our team has the best in front of them between tooling, equipment and support, no matter what vehicle we are called to service,” he explains.

“One of the challenges in the calibration world is, if you’re going to do it really well, the commitment to tooling and training is only part of it — you have to invest in your people as well,” he says.

“We really try to, from a comp perspective, set them up to be successful, let them have the autonomy to make the calls they need to. We’ve invested heavily in our external service capabilities as well as our internal tech support.”

Support is key, he says, because techs are conscious of not only looking professional but being professional.

“Our team has been instilled with a sense of urgency. We have to think out of the box. We need to come and solve the problem, because if our customers could solve the problem themselves at their shops, they’d be doing it.”

As odd as it may be to admit, McGuire sees a silver lining from building his business through the pandemic.

“In a sense, looking at where we’ve grown in the span of literally the two-year mark, I almost feel that had we not had some of the disruption to the market, I don’t know that we would have been able to have the success we’ve had, because it’s given us time to hone our trade. It’s actually set us up to do this better. The minute our service level is not what it’s desired to be from our perspective and from our clients’ perspective, it’s over,” McGuire says.

“You can have really nice equipment and really good technicians, but if you can’t support the service level, you don’t have any value.”

McGuire believes in letting the talent be used where it’s most effective. To support them, Precision has a team that handles scheduling and invoicing, so the repair techs can do their jobs without distraction.

“I want my technicians doing what they’re good at — fixing cars. That’s where the customer’s going to win, and that’s where we’re going to win as a business.”

McGuire explains that the systems used to dispatch repair technicians allows all parties at Precision Diagnostics to see what’s going on. “The tech has a real-time view of what’s in the field, so if he’s, say, in the north side of Milwaukee, and three new jobs pop up there, it’s visible to everybody. There’s an expectation that when you see it pop up, you’re either accepting it or you’re declining it because you’re on another job; but it gives the techs some autonomy to handle jobs in their area.

“On the invoicing side, it’s important to the shop that they get that paperwork, so they can close files, but we don’t need our guys spending time sitting in the van creating an invoice when the job is done. As soon as the job is complete, our central office gets copies of what was done, along with a copy of anything that’s pertinent to the invoice. The body shop then has an invoice in hand within minutes.”

McGuire admits that his initial plan for Precision’s growth was in service to collision repair — the reality of ADAS made him expand his thinking. “An independent glass company called me just after we opened and desperately needed someone to calibrate a forward camera in a certain vehicle. This became such a big relationship with this one customer that we provided an extra full-size calibration frame setup because he had so much work for us. This guy’s doing a dozen to 15 windshield calibrations a week at one place outside of Madison.

“Everything’s a lot more mobile, and that’s one of the things that Autel did really well with a mobile calibration frame they developed. We were one of the first in the country to get our hands on those, and I think we have about 18 of them now.

“We’ve found glass companies have a huge need, and we love working with them. A lot of people have no idea that when they get a windshield replaced it needs a camera calibration. We can help prevent the need to go back to the dealer for that.”

In addition, McGuire says his customers include transmission shops and mechanical shops. “They get into having to reprogram a power control module, powertrain control module or engine control module, but they just don’t have the equipment. We do a lot of wire harness repair, connector replacement. We’ve gotten deeper into key fob programming and replacements.”

McGuire says his team puts an emphasis on convenience, but that definition can vary from market to market.

“In Wisconsin, it was easy to install standalone calibration centers, because I understood the logistics of the Wisconsin market really well,” McGuire says. “And in those markets where we have a calibration center, we actually have flatbeds on the road, to pick the car up at the shop. If I can prevent a body shop from having to throw two guys in a car and lose a half-hour of productivity, it’s a big satisfaction winner every day. If we can make that happen, the bigger picture takes care of itself.”

Stand-alone centers don’t necessarily make sense for other locations however, McGuire explains.

“In certain markets, we feel calibration centers are required. In others, we’ll do the jobs from a mobile capacity with bigger vans in those markets, so we can actually put more stuff in them.”

McGuire cautions against thinking that the mobile service is somehow less impressive. “The last van we built out had over $148,000 in improvements and equipment.”

The investment speaks volumes. “Enterprise car rental is a big account,” McGuire says, “and they’re very specific on OE health checks only. For them we’ve made a significant investment in having the OE equipment on board as well. They sent a regional VP out to look inside one of our vans, and he was astonished. He said ‘You’ve got literally an entire working dealership in this van, for every company. I’ve never seen anything like this in my life.’”

Preparation takes the place of panic.

“We don’t want to be in a situation where our guy is in the field and doesn’t have the right target or tool,” McGuire says. “So, when that service request comes through, we ask for very specific information from the shop. In fact, to make it even easier, our website allows them to just drop a copy of their repair order. This gives us everything we need and saves them from having to fill out a bunch of fields.”

Communication is key, says McGuire. “As you go into a market in a mobile way, you start to know your shops. You start to know who’s got space where you can work, who’s got an area that lines itself up well. Our goal has not been to go out and work with every shop; it’s to work with the ones who are progressive-minded, who care about that end result and want to do it right.

McGuire’s team has been able to partner with mechanical shops in certain markets, to handle alignments and other mechanical service. The goal is to eliminate steps for the end customer.

Of course, to do this at this scale requires considerable investment, McGuire acknowledges. Part of this investment includes partnerships with suppliers like Autel.

“Autel has done a really nice job of getting us involved in some new product development and getting things in our hands very early in their inception. They’ve come out with a number of products and, in the case of the IA800 tool, we were the first ones in the country to have it.

“As a beta tester for Autel, we’ll get items like that a couple of times a year. We get to be involved in some of the technical development with them, offering real-world feedback on the product’s operation,” he said.

“They’ve really made some significant product upgrades. For a non-OE provider, they are truly cutting edge, and what I love about their stuff is its comprehensiveness. What I can do with their tooling across multiple platforms is unmatched. Our techs really love the flexibility of their products.”

In addition, Precision Diagnostics does a lot of work with Hunter on alignment systems and equipment in the physical locations. “They’ve been really good to work with. Hunter knows that when we put one of these together, based on the models we’ve done in Wisconsin, it makes such a big statement to our technicians.”

It also makes a statement to the suppliers themselves.

“When the Hunter guy walked in our first calibration center, you could tell he was really impressed.”

McGuire says for its rapid advancement, there’s still a great mystery about ADAS in much of the industry. “There’s almost kind of this mystical unknown about ADAS calibrations, so much of an industry awareness that’s lacking,” he says. “Even we’re still learning every day. I sure don’t know everything there is to know about it. I mean, it’s constantly changing and evolving.”

So, keeping up with training isn’t just a challenge but a requirement, and an investment that is as impressive as with equipment.

“We are on the waiting list right now for the electric F-150 Lightning,” he says. “As soon as it’s released, we’ll use it as our own R&D project — because we see the evolution into EVs as a huge corner for our guys down the road.”

Obviously, the investment in upcoming technologies is paying off.

“We’ve got insurance companies actually coming to us, asking for help understanding some of the calibration requirements of the new cars,” McGuire says. “When you start reading OEM service information, there’s a big difference between ‘must’ and ‘recommended’ service requirements.”

McGuire likens the current calibration world to that of a gold rush, with some unscrupulous prospectors trying to take advantage of unknowing clients. “We believe, if we come in and do a good job, treat our customers fairly and can explain what we do and how they can get paid for it, we’re going to have that long-term tenure with them. But if we don’t bring value, then we shouldn’t have your business.”

For a new business concept, McGuire and Zielke follow an old-school business model.

“We want to come in and give our customers something of value, treat them well and be a trusted advisor for them,” McGuire says. “It’s working. It’s refreshing that people still want that.”