You only have so many hours in the day. With the right attitude and attention you can easily create and implement procedures to create value for your customers, so they understand and want the skilled services you can provide. Here are some great tips to help you make your alignment services profitable and productive.

1. CHECK SELF-CALIBRATING STEERING ANGLE SENSORS

Self-calibrating steering angle sensors use inputs from the accelerometers to determine if the vehicle is traveling straight and resets the steering angle sensor. But, on most of these systems, some enabling criteria must be met, like a minimum speed and a defined amount of steering angle. This is why it is always a good idea to test-drive a car after an alignment. It is also always a good idea to perform one lock-to-lock turn before leaving the alignment bay.

2. DON’T FORGET THE TIRES

Tires are not perfect. Like every part on the car, tires and wheels are made within tolerances. These tolerances include runout and radial force variation. The changes in uniformity and stacked tolerances in the tire and wheel can cause a steering pull.

You can try rotating the tires to cancel out the pull or at least move the worst tire to a non-steering axle. But, during the next rotation the pull could return.

Some balancers simulate how the wheel actually performs on the vehicle by applying force over the entire tire/rim assembly. With its patented sensors, Hunter’s GSP9700 balancer pinpoints the lowest point of a rim (for runout) and the stiff area of a tire’s sidewall under load (for radial force variation). Then, the patented software automatically determines how the assembly can be match-mounted to offer the best ride quality.

The balancer can then look at the entire set and place the right tire with the right rim and assign the correct position so a pull can be canceled out.

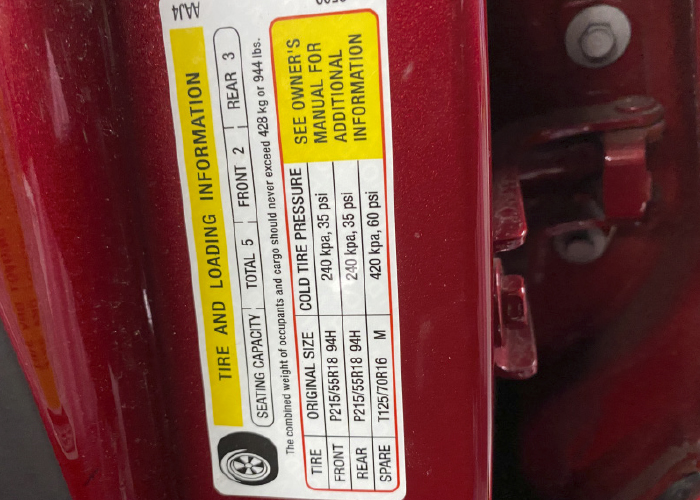

3. INFLATION FIRST

When doing your pre-alignment inspection, always check tire inflation pressures because a low tire will pull. It’s also important to note tire sizes. A car will pull toward the side with the smallest tires or the side with wider tires. A wide tire offers greater rolling resistance than a narrower tire. Wide tires also tend to be more sensitive to road crown steer than narrower ones.

4. HITTING THE BULLSEYE

When doing an alignment, always aim for the midpoint or preferred setting within a range of acceptable specs. And, when that isn’t possible, make sure you’re at least within the range of acceptable specs.

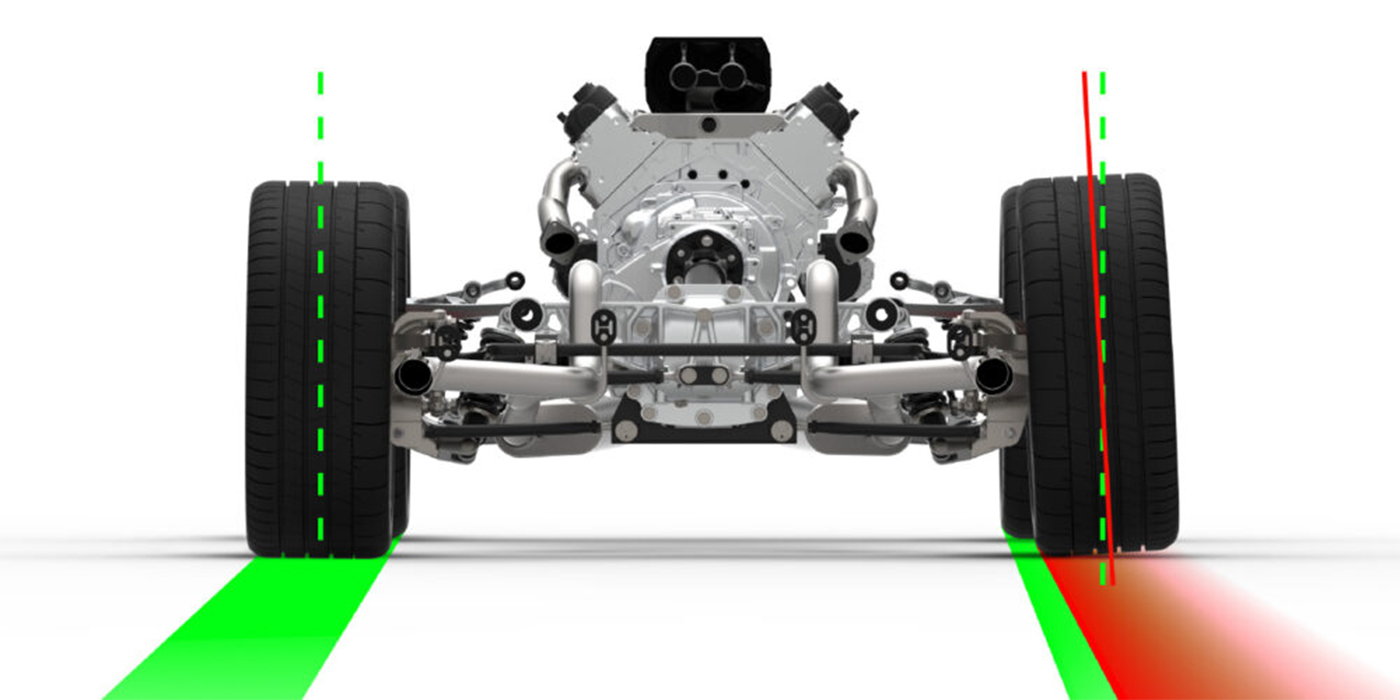

Also, try to minimize cross-camber by keeping the side-to-side camber readings within half a degree of each other. If camber is not within half a degree side-to-side, it may create a steering pull.

If the wheels won’t align, or if the wheels on a vehicle with a “nonadjustable” suspension are out of range, then something is bent or worn and needs to be straightened or replaced. Don’t just set the toe and let it go. If camber is off the mark, find out why and see if it’s worth fixing. A weak or broken spring, a collapsed control arm bushing, a mislocated strut tower or engine cradle, or a bent strut or control arm can throw camber off as well as Steering Axis Inclination (SAI) and cause a steering pull.

As with rear toe, rear camber is also important on vehicles with independent rear suspensions. A sagging suspension (typically due to a weak or broken spring) will often cause a rear camber problem, so be sure to inspect the suspension carefully if rear camber is off.

5. FIGHTING THE CROWN

Steering pull that’s caused by road crown can sometimes be compensated by adding positive caster to the left front wheel compared to the right front. You don’t need much, just enough to offset the road crown which slopes to the right. The trick is to find the right amount of caster that keeps the vehicle going straight and keeps your customer happy.

If caster is out of range, check for worn strut or control arm bushings, a mislocated MacPherson strut tower or a bent lower control arm.

6. PROBLEM VEHICLES

The toughest alignment job is the “problem” vehicle that keeps coming back because it’s wearing out tires or isn’t steering straight no matter how you align the wheels.

Sometimes, the real problem is undiagnosed collision damage, such as a bent strut, steering arm, control arm, mislocated strut tower, subframe or engine cradle that is affecting alignment. And noted earlier, rear axle steer may be causing front toe wear, as well as a steering pull.

A problem vehicle may have misaligned structural members that position the front or rear suspension. Assembly line build tolerances have tightened considerably in recent years, but nobody is perfect. Mistakes are made, and the so-called plus or minus 1 mm build tolerance is more myth than reality, in many instances.

7. TAKE NOTES

A service writer’s note to the technician should answer the following questions:

- Why does the vehicle require an alignment?

- Does it pull? Which way? When?

- What is the vehicle used for?

The service writer should include all relevant information. Never worry about writing too much.

8. INFORMATION BELONGS IN THE ALIGNMENT BAY

Back in the days of CD ROM-based information systems, if you needed the torque specs of an adjustment procedure, you might have had to look them up in a service manual that was always missing the years you really needed, or you had to go to a computer in the front office to look up the information. With most modern alignment consoles, the service information is incorporated into the core operating software of the system. Most of these systems are PC-based and allow you to go onto the internet to look for information and even order parts.

9. PRICE ALIGNMENTS FOR THE VEHICLE, NOT FROM A MENU

There have been dramatic changes in vehicle technology and suspension designs in just the past decade. From “net build” vehicles made with only front toe adjustments to cast aluminum control links, the alignment process has changed with vehicle models. It is up to you to price an alignment accordingly. Alignments are not loss leaders.

10. TEST-DRIVE THE VEHICLE BEFORE IT’S RETURNED TO THE CUSTOMER

A simple test-drive can reveal a lot of problems that might have been otherwise overlooked. Sure, test drives take time, but so do comebacks. Think of it as a final quality-control check.