Every April, our sister publication Transmission Digest covers issues facing the hard parts segment of our industry. Hard parts are distinct from soft parts (kits) in that used and rebuilt parts make up a portion (often a significant portion) of what retail shops purchase to repair transmissions on their benches. Traditionally, there has been a patchwork of sources that took in scrapped transmission cores and tore them down to harvest parts that then were available for purchase, either directly from the parts supplier or via parts distributors. One of the trends we’ve seen over the years is distributors harvesting their own parts.

Like seemingly everything else in the world, hard parts are subject to current supply chain shortages. Not only do the OE new parts suffer from insufficient availability, so too do the alternative aftermarket new parts that are often manufactured overseas. With a shortage of new parts, there is increased demand for cores and used parts, resulting in the shortages being reported throughout the industry.

As shops seek parts to repair the transmissions they’re seeing in the bays, the transmission remanufacturers are scrambling to find those same parts. Purchasing large quantities of parts in bulk, these volume builders often get first access to what is available. As would be expected, constrained supply leads to backorders and higher parts prices.

Most industry suppliers expect that the supply chain issues will gradually be solved as the world catches up with demand in the current Covid-recovery economy. Until the easing of supply shortages becomes reality, builders who have been accustomed to ordering hard parts with kits are finding that they are having to look far and wide to purchase necessary hard parts.

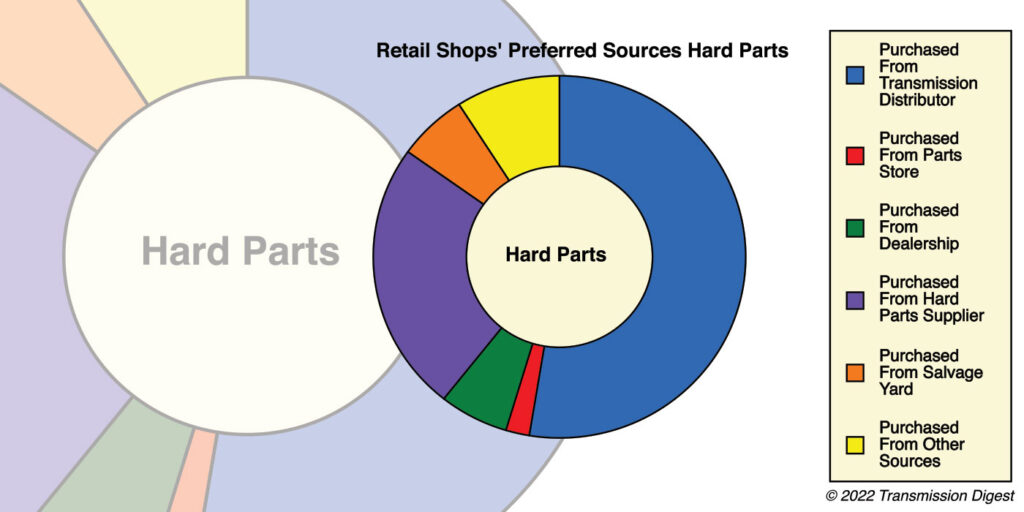

The image at the top of this page represents results from the 2022 Transmission Digest survey of retail shops tracks the various sources those shops rely on for acquiring hard parts. The results don’t provide a breakdown of the original source of the parts. Here we show where the order is placed by the rebuilder.

Hard parts ‘Transcabulary’

OE New: A part purchased from the OEM transmission manufacturer, mostly though new car dealerships or from contracted aftermarket distributors. These parts are typically the identical part used to manufacture the unit, occasionally upgraded to address wear and/or failure issues.

Aftermarket New : A part most often reverse-engineered to be identical to the OE part. Occasionally these are upgraded to address issues that are recognized after the unit has been in use for some time.

Remanufactured: Also known as reconditioned or rebuilt. These are parts that have been returned to near OE specification. For instance, pumps are often resurfaced to remove the effects of normal wear.

Good Used: Parts that have been visually inspected and sometimes measured to eliminate those parts with excessive wear or that are otherwise unfit for use in a rebuild.

Used: Parts that have been harvested from torn-down transmission units.

Core: A transmission that can be torn down to retrieve needed parts.