Electric Vehicle (EV) service is inevitable. It’s only a question of when you decide to start. The ultimate timeline likely has more to do with your location than anything else, because your business depends on volume and the occasional straggler EV through the door won’t do much for you.

But, is it better to start small when you have time to familiarize yourself with the technology and can afford the associated learning curve? The alternative is to wait until it becomes a necessity to stay busy and then suffer through the related growing pains. It may be years before EVs really gain momentum in your area, but on the other hand, time moves fast, and shouldn’t you be prepared?

Maybe you have a technician who’s interested in the technology, or someone who’s willing to learn, and it could be a good opportunity to pursue some education and start to get the particulars lined up. Some of the first questions will be what do you need for tools, and what do you need for safety?

The First Steps

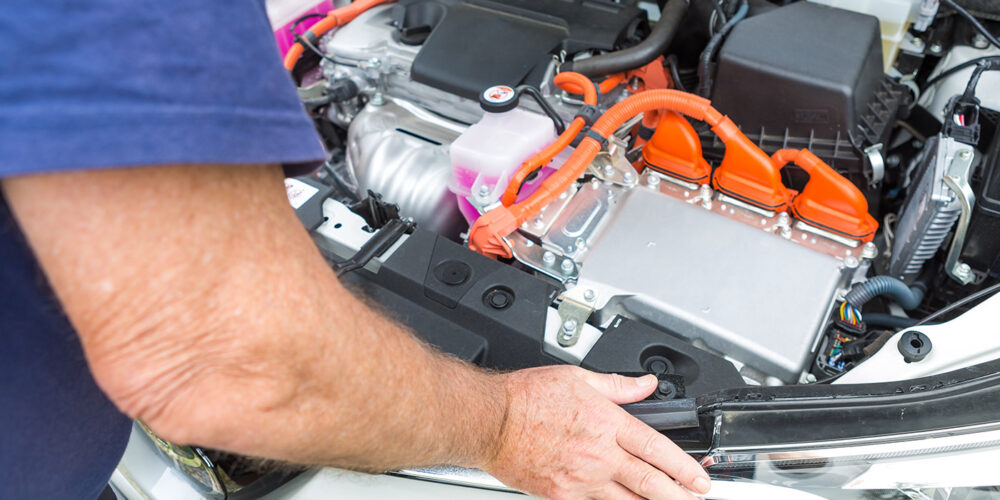

Let’s first look at the work area. The high voltage and amperage from an EV can kill. There’s no two ways about it. But, with the proper precautions, they’re as safe to work on as anything else. The most important thing to train is the safety mindset, and it begins with not only the personal safety of the technician, but the safety of everyone else.

When servicing the electrical system on any type of hybrid or EV, the entire work area should be marked with cones, some type of barrier chain or tape and warning signs, all colored and designed to indicate that this type of electrical work is taking place. Not only will this warn other technicians of the work that is occurring, but it’s a safety matter for customers, as well. No matter how hard we try and the policies we post, there’s always that one customer who thinks we want them leaning on the fender to inspect the progress on the car…you know the ones.

In addition to cordoning off the area, shops need to be equipped with an insulated rescue pole, which, in the event of an accident, allows someone to safely pull the technician away from an electrical source.

The technicians themselves must wear insulated safety gloves rated and designed to handle high voltage, but these gloves need to be checked prior to each use for tears, cuts, leaks or damage that could allow electricity to travel. This is a procedure that is good to document and keep in a safe place where the gloves are stored, so these steps are never missed or overlooked.

The Tools

When I say you need insulated tools, you may think Captain Obvious is in the house, but there are two different types of tools you can get, insulated and non-conductive. An insulated tool is a regular tool, just like what we use now, but coated with a non-conductive material. Even if the tool itself conducts electricity, the insulation prevents it from flowing. The drawback to insulated tools is if the insulation is damaged or worn in any way, it can allow electricity to flow, and the insulation must be inspected on a regular basis to make sure it is intact.

Non-conductive tools aren’t metal like normal tools. They are made of strong composite materials which are non-conductive, eliminating the worry of damaged insulation. There may be certain features that contain metal – for example, sockets still have metal inserts – but the rest is composite, eliminating any conductive path to the technician.

The bottom line is that any tools you use must be rated to the proper voltage and conform to the latest International Electrotechnical Commission (IEC) Standard.

When it comes to diagnostic tools, you’ll need a multimeter that is rated to CAT III in order to handle the high voltages. It’s important to note that there’s more to this than just the risk of damaging a meter that’s not rated for it. There’s potential for an arc blast or explosion when using the wrong equipment.

Shop Equipment

With shop equipment, there are a couple points you’ll need to keep in mind. One is with two-post lifts. “Lifting electric vehicles presents unique challenges because EVs tend to be heavier and have harder-to-reach lift points than traditional vehicles,” said Jeff Kritzer, BendPak president and CEO.

A lift that is designed for EV service not only is engineered for the additional weight, but the lift arms are designed to access the lifting points for easier and safe lifting. At minimum, you may need to purchase different lift pads in order to safely and correctly lift an EV. Don’t forget the batteries on an EV are often the entire floorpan, so use extreme caution when lifting these vehicles and always use the proper lift points.

The batteries are also very heavy, and there are special lift tables designed for removing them. The advantage to this equipment designed for EV service is that it is still just as useful for the vehicles you work on today. “As electric vehicle sales grow exponentially, OEMs, dealers and independent repair shops are looking for ways to make replacing heavy high-voltage battery packs safer and more efficient,” said Kritzer. “Our EV2400SL eliminates any manual lifting or lowering of the battery pack. And, since we know most vehicles on the road will continue to be powered by internal combustion engines well into the future, the EV2400SL also works perfectly as a powertrain lift, providing maximum versatility and return on investment.”

The other most prevalent piece of equipment is an A/C machine. EV and hybrid A/C compressors operate off a high-voltage motor, and, therefore, the A/C oil cannot be electrically conductive. The wrong oil can pose an electrocution hazard, as well as cause the check engine light to come on in some cars if they detect electrical connectivity in the A/C compressor. For this reason, new A/C machines are designed with a special function to flush oil from the hoses in order to prevent cross-contamination of the systems.

The Last Word

EV service, more than anything, is about safety, and safety starts with training. As important as the tools, training should be considered mandatory, and perhaps a precursor to all the rest.