When it comes to chassis parts, simplicity is the key to success. Overengineering components can not only make it more difficult to perform repairs, but it some cases may cause earlier repairs/failures in certain scenarios.

What is overengineering?

Overengineering is often described as designing a product or solution in an unnecessarily complicated way where a simple solution had been shown to have the same efficiency, or is even more effective than the original.

In the aftermarket world, the OE part is where the journey starts. It begins with testing and understanding the original component, and then looking for ways to improve the design, materials used, and so on.

However, some manufacturers can overengineer their solutions. This is especially true for chassis products, which have the added complication of high and low-fiction, as well as high and low-tech.

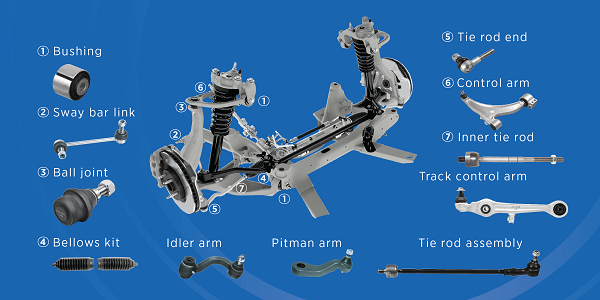

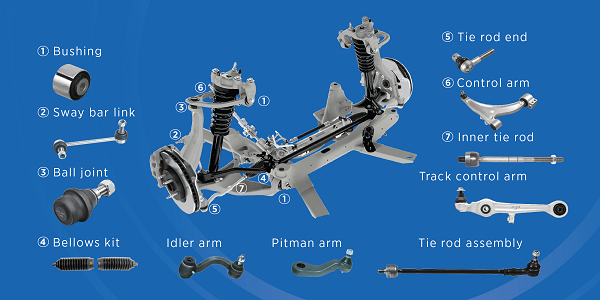

Chassis: High and low-friction parts and technologies

When it comes to chassis, OE instructions often include information if the part is high or low-friction. But what does this mean?

High-friction: These components typically generate more heat as they experience more pressure or other forces. Greasing is more commonplace on high-friction components as it helps to reduce the heat buildup, which prevents additional pressure on the part and can extend its lifespan.

Low-friction: Low-friction parts, while still giving off heat when in use, don’t do it at a rate comparable to their high-friction counterparts. Greasing is less common in low-friction parts, as it’s generally not needed.

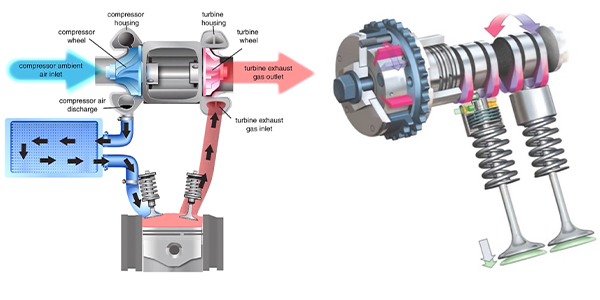

In addition to high and low-friction, there’s another aspect that has to be considered: whether the part is high or low-tech. As technology and part designs have continued to improve, it’s more common to see low-friction/high-tech chassis components on today’s vehicles, whereas high-friction/low-tech parts are typically more common on older vehicle models.

High-tech: These parts are engineered with an overall more intelligent design, which often results in a lower-friction design, eliminating or reducing the need for additional greasing in most instances.

Low-tech: Low-tech parts are not as sophisticated in their design as their high-tech counterparts—but that’s not necessarily a bad thing. Low-tech components generally require greasing more frequently as they experience a higher amount of friction.

Debunking the myth: why every replacement part doesn’t need to be greaseable

Although greasing is common on high-friction/low-tech parts, many low-friction/high-tech components are now engineered to not need additional grease and are pre-greased and sealed for the life of the part. With a high-friction/low-tech component, a greaseable solution is often recommended, but having a previously high-tech/low-friction OE design converted to a grease-able aftermarket design may open the possibility of pre-mature failure caused by:

· Dirt and other contaminations

· User error/technician not greasing the part

In general, any time a part needs repairs, it creates a window for new errors to crop up. A low-friction, high-tech part is desirable in most replacement scenarios, however, a high-friction/low-tech component can also be the perfect match for an older model. To minimize additional and unnecessary repairs, always be sure to consult the OE’s guide for the specific part to understand the best repair fit.

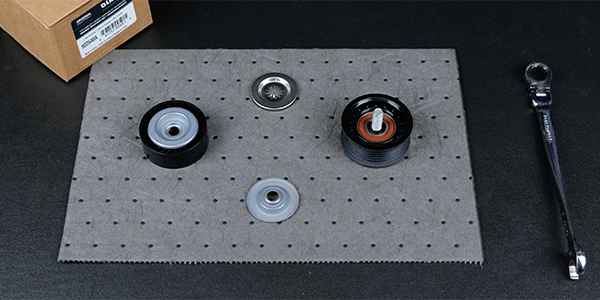

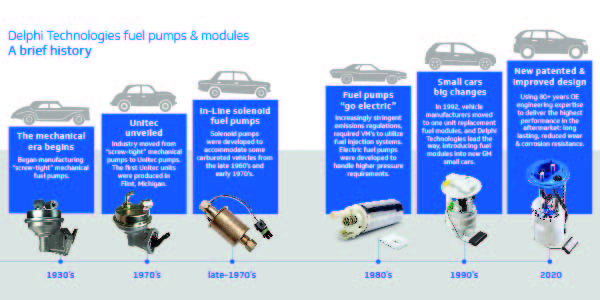

Delphi’s engineering difference

Our parts are built with an intent-driven engineering mindset. We carefully test and analyze each OE component and perform a multitude of tests to ensure our products are intelligently designed and built with purpose—including greasing.

When looking at potential improvements to the OE product, here are a few of the things we do for chassis parts:

· Perform a dimensional analysis to understand potential design enhancements

· Conduct material analyses to better source materials, develop lightweight solutions and more

· Analyze the need for grease on parts in conjunction with dimensional and material analyses

And before any of our parts are shipped, we subject them to rigorous testing to ensure they’re built to latest in the toughest scenarios. These are just a few of the tests we perform:

· Extreme temperatures (-40°C – 120°C)

· Fatigue and crack detection

· Dimensional and material analysis

· 3-axis

· Salt spray (720 hours)

Ready to learn more about high and low-friction and tech chassis parts from Delphi Technologies? Join one of our senior technicians as he takes you through everything you need to know: https://youtu.be/WpovV1X2T5w

Steer into your Delphi Technologies future today. Visit us at delphiaftermarket.com for more information on our chassis offerings.

Delphi Technologies is a brand of BorgWarner Inc.

This Article is Sponsored By: Delphi Technologies