I know it might seem like we are “jumping the gun” by having an article on Tesla battery pack replacement, but the first Tesla models are now a decade old. Also, high-voltage propulsion batteries have been installed in vehicles for more than 20 years. So, even if your shop doesn’t target electric vehicles, chances are you have already run across a hybrid with a battery pack causing codes and diminished range.

While we are focusing on Tesla for this article, the precautions and procedures apply to many hybrids and electric vehicles when servicing high-voltage systems. You should not be afraid of working on battery packs. But, you should be mindful of the potential damage these high voltages can cause. Training is available online for dealing with high-voltage systems and access to the service information to get around any problems.

The service information for Tesla is available. You can set up an account at the website service.tesla.com to view the service information for the procedure for free. Also, scan tools are starting to become available with coverage for Tesla. But, for many service procedures, the iPad-like interface becomes the scan tool.

12 Volts Forever

Almost every hybrid or electric vehicle includes a 12-volt battery and architecture, just like conventional internal combustion vehicles. On most hybrids, the high-voltage battery might only be connected to the inverter, motor and HVAC system. The conventional 12-volt system does just about everything else. But on an EV or hybrid, the 12-volt battery is the master of the high-voltage systems.

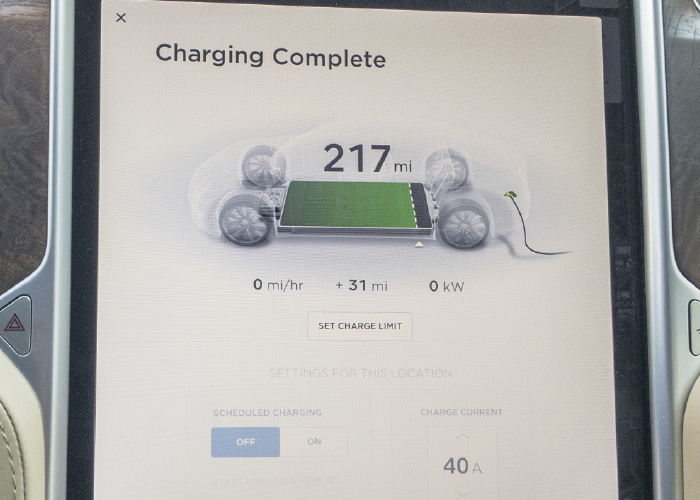

In almost all Tesla models, the high-voltage battery powers the motors and charges the 12-volt system. The 12-volt electrical system controls the interface with the battery and charging system. Most importantly, the 12-volt system can de-energize the high-voltage system so you can remove the high-voltage battery.

Disconnecting the 12-volt battery in the trunk or at the base of the windshield will de-energize the connections on the high-voltage battery. Before you do that, take a look at the service information. On the Model S, they advise the power windows to be rolled down. This is because when the door is opened, the window drops out of the track on the door. If the battery is disconnected, opening the door will damage the window and weatherstripping.

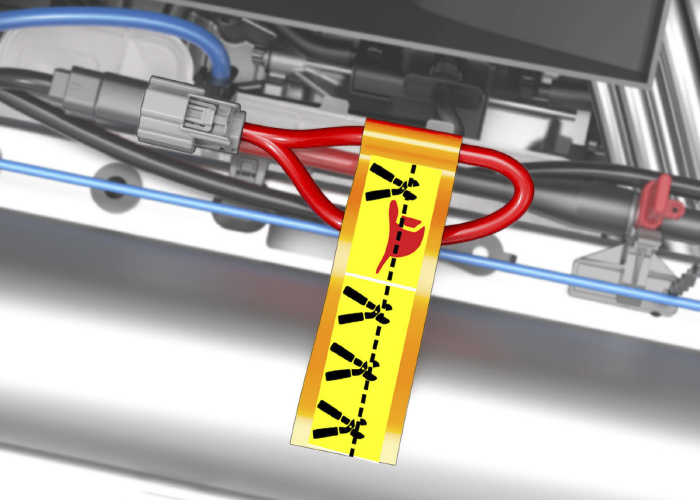

On most Tesla models, the first step to replacing the 12-volt battery or high-voltage battery pack is disconnecting the “first responder loop” (you don’t have to cut it, just disconnect it). The first responder loop disables low-voltage power going to the airbag circuit, but it also signals the battery to go into lockdown.

Cutting or disconnecting the first responder loop stops low-voltage power from going to the high-voltage battery pack. When the 12 volts are not there, multiple switches isolate the battery from the vehicle and battery modules inside the pack. It is a safety item that prevents the battery pack from shorting during a collision.

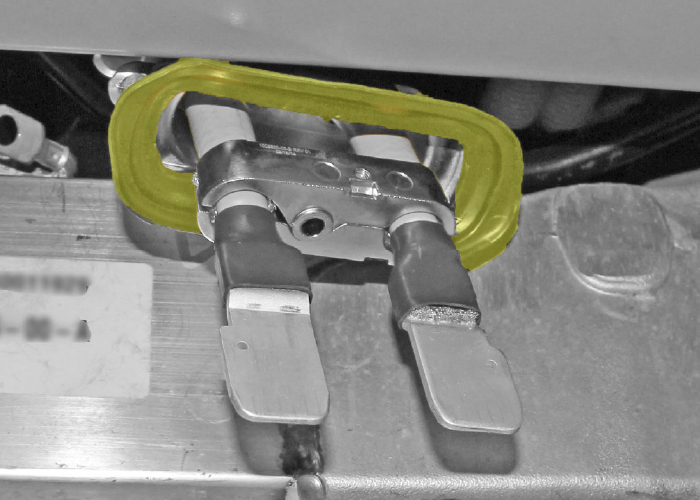

The battery pack also has a fuse that is not a fuse. This is a device that can quickly cut the connection to a vehicle. The fuse uses a pyrotechnic charge to cut the wires to the battery. This is typically set off by an impact, deployment of the airbags or sudden change in current flow.

Always treat the pack and the high-voltage components as if they are live because the pack will still have stored energy within the cells, and it is not known if other high-voltage parts have been damaged. Treat every battery pack and the orange cable as if there is high voltage in them. There is no way to instantaneously discharge the energy inside the battery pack when a vehicle is serviced. There is always stored energy in the battery cells.

The most important advice is to follow the service information for the sequence of procedures to de-energize the system and remove the battery. You should never take shortcuts.

What is in a Battery Pack?

Whether it is an EV or hybrid, it will have a battery pack made of groups of cells wired in series. A single cell might generate only 1.2 volts. If you put 168 cells in series, you will get approximately 200 volts. This is how they generate the high current. The cells in series are not all hardwired in series or chain, and they are connected to bus bars to decrease complexity while increasing capacity.

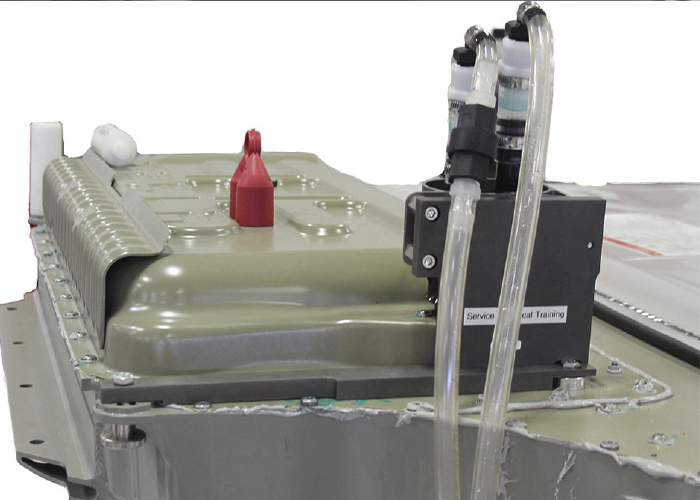

An early Tesla Model-S battery will have 14 groups containing more than 450 cells. The pack might have more than 7,000 cells. Each module has a computer to measure the cells’ internal resistance, voltages and temperature.

Battery pack cells are a chemical reaction that generates power. Over the life of the cell, it degrades. This degradation changes the internal resistance and how the battery charges and releases energy. In addition, heat and vibration can degrade the individual cells. As a result, over the life of the battery pack, one module or group can start generating a lower voltage than the others. When this happens, the battery pack can become imbalanced.

If the pack is out of balance, the effect is a temporary loss of capacity: when charging, you have to stop when the most highly charged cells achieve the maximum targeted voltage allowable voltage and, when discharging, you have to stop when the lowest charged cell group hits the minimum allowable voltage. In either case, the cells would be damaged if the charger didn’t stop. So this is the “balanced” part of the charging equation. But, all you have to remember is that the battery is only as powerful as the weakest cell.

Replacement Options

Only specialists should try to access the individual modules in the battery pack. However, there are several replacement options. The first option might be to purchase a new battery pack from Tesla. The second option might be a salvaged battery from a crashed Tesla. But, there is a growing market for reman battery packs.

Remanufacturing high-voltage battery packs typically involves balancing the battery modules. This is performed by selecting modules from several battery packs with similar voltages and capacities.

Are you going to see a sudden demand for Tesla service at your shop? Probably not. But, you will start to see an increase in the volume of vehicles that need service to the high-voltage system and battery packs.

10 Tesla Battery Pack Service Tips

• When removing or installing the high-voltage battery, Tesla advised technicians to use a cordless drill and not a cordless or air impact. This is because vibrations from an impact tool can cause sparking from the rapid-mate connector.

• Lower the driver’s side window before disconnecting the 12-volt battery. Failing to do this can result in damaged weatherstripping and a broken window on some models. This is great advice for most late-model cars and trucks with windows that lower a small amount when the door handle is pulled.

• Service information can be accessed for free at service.tesla.com.

• Follow all the procedures when removing or installing a battery pack.

• Replace gaskets for connectors that pass through the outer case. Some gaskets also need to be lubricated.

• Avoid reusing fasteners that hold the battery pack to the body. Most are Nylok fasteners that should never be reused on any vehicle.

• Never exceed 25 psi when flushing or filling the coolant from the battery pack. Excessive pressure can damage the channels and hoses that run between the modules.

• When lifting a Tesla, use the correct mounting points and adapters. Damage can occur if an arm slips.

• When lowering or raising the battery pack into the vehicle, use a jack or lift that can support and move it properly. The battery can weigh as much as 1,200 lbs. Trying to support the battery on a shop cart, trolley or furniture can result in a damaged battery pack and rapid-mate connector on the vehicle.

• Explore the service menu before and after the repair. If you have the service information, you can also unlock items like being able to bleed the cooling system.