For more than 100 years, the aftermarket parts and service industry has adapted to changing vehicle technology. The industry shifted from servicing steam to electric to internal combustion … and now back to electric. With each new innovative technology, the initial reaction is worry over accessing the tools, procedures and parts to service electronic fuel injection, anti-lock brakes, emission-controls systems and other high-tech components. But, in every case, the innovative and resourceful aftermarket industry adapted to the new requirements for keeping America moving. We engineered replacement parts, provided procedures and training, and kept our promise to the motoring public that “if you can drive it, we can service it.”

Today, the rate of change in vehicle technology has never been greater and the challenges associated with keeping up and thriving are daunting. Advanced driver-assistance systems (ADAS) hold the potential to dramatically reduce traffic fatalities and injuries with automated systems designed to brake automatically, maintain the driving lane, detect pedestrians and other hazards of putting the vehicle in drive. The sensors, cameras and other whiz-bang technology are becoming required on almost all new vehicles in 2022 and are often part of common aftermarket repair procedures. While the technology has become almost ubiquitous, the industry’s commitment to training, education and service practices has been lagging. Increased awareness of the implications of ADAS is essential to retain customer confidence in the aftermarket.

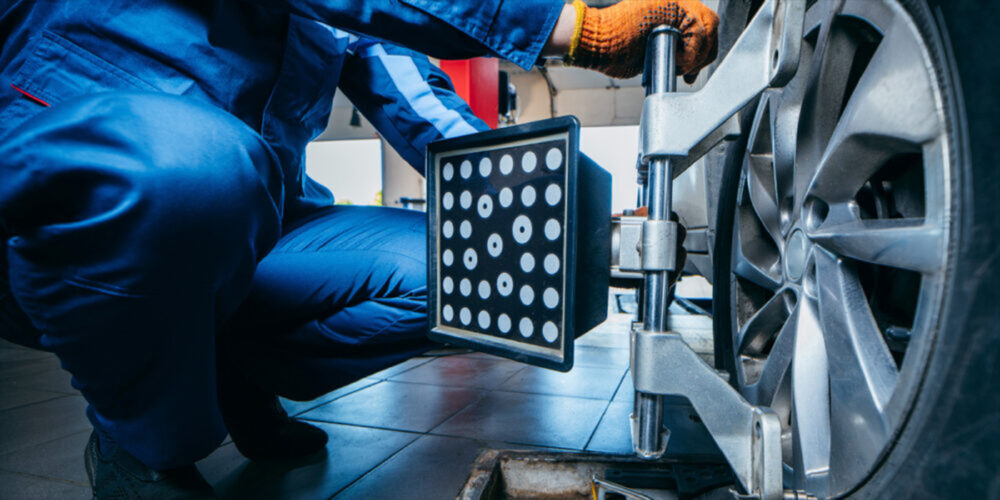

There are a handful of issues that everyone in the aftermarket supply chain should be mindful of the next time an ADAS-equipped vehicle comes in for service. The first is to recognize when a routine service job is affected by, or affects, a sensor or component that is part of an ADAS system. For example, a wheel alignment affects the aim of the forward-facing collision-detection sensor. Replacement of a radiator or A/C condenser may affect the alignment of the adaptive cruise-control sensor. Recalibration and aiming of these critical safety components is essential. Recognizing when this task is required is step 1.

The Call for Consistency

OEM documentation of ADAS service procedures is incomplete and inconsistent. There is no category for ADAS in the OEM sources – references to parts and procedures are scattered across many vehicle systems. The leading technical service publishers have done their best to normalize the inconsistent nomenclature across vehicle makes and to draw attention to the ADAS procedures when they are required. One leading service information provider has a big red button labeled “ADAS Information” that appears on the screen for all vehicles and services where it is relevant. The button gets hit 12% of the time when it should. Important ADAS procedures and cautionary information are going unheeded.

In the interest of space and time, I’ll only briefly list some of the other issues and “baggage” that go along with servicing ADAS-equipped vehicles:

- The expense of the calibration equipment and targets required to aim the cameras and the like. ADAS calibration packages start under $10,000 and go up to $25,000 and more, depending on the breadth of systems to be calibrated and the vehicle makes being serviced.

- The space required can be prohibitive. Every shop doesn’t have a bay the size of a basketball court to properly aim forward-facing cameras and sensors.

- Business insurance and liability protection is more important than ever. Top shops have always had comprehensive protection against something happening to a vehicle they serviced. With black boxes recording the state of every vehicle system in the event of a wreck, no shop can afford to ignore the required procedures on a critical safety component.

Aftermarket parts manufacturers are already listing ADAS components in their catalogs. It will be interesting to see how warranty and other policies will evolve to require documented proof that the part was installed properly and calibrated completely before any claims are paid.

Threats And Opportunities

I have two closing thoughts about the opportunity and threat posed by ADAS in the aftermarket. The number of ADAS-equipped vehicles already numbers in the tens of millions, and nearly every new car and light truck will include ADAS from this point forward. A shop can commit to the tools, training and targets required to follow the required procedures in every appropriate service job – or not. Those that do will continue to be the preferred service choice of their customer. Even OEM dealers that don’t have the space or equipment will seek out those independent shops. But, others will be required to turn away an increasing number of routine aftermarket service opportunities – or assume a tremendous liability by cutting corners or ignoring procedures designed to save lives.

Here’s my No. 1 reason why the industry needs to make a serious commitment to performing ADAS repair by the book 100% of the time – maintain the trust of the motoring public in the independent aftermarket. A decades-long battle has been fought and millions of dollars in industry resources spent on the Right to Repair Issue. Seventy-five percent of the voters in Massachusetts effectively said, “I trust the aftermarket with the data associated with my vehicle and I want them to have the right to repair whatever goes wrong.”

We have been fortunate not to see headlines about cars that mysteriously slam on the brakes at highway speeds because their collision-avoidance camera was off by 2 degrees and “saw” an overpass or a construction barrel instead of the open road. There is no margin for error in these amazing safety systems. All of the goodwill and consumer confidence in the resourceful and innovative aftermarket gained in the Right to Repair battle could be un-done with a few sensational news stories about failed ADAS service.

There is a lot of good work being done by the industry associations and committed volunteers to advance standards, documentation and more affordable tools to service the cars of tomorrow. But, today, we’ve got to treat every late-model car with a higher level of professionalism than ever before. It’s what your customers deserve and are counting on.

Scott Luckett is vice president, Industry Strategy for GCommerce Inc., where he has responsibility for industry partnerships and major account development. Previously, Luckett rose through several positions at the Auto Care Association over 17 years and as CIO had responsibility for the Technology Standards Committee, the Aftermarket eForum, the Telematics Task Force and the National Catalog Managers Association (NCMA). Before Auto Care, Luckett was a sales management executive at a local automotive WD and prior to that was a top sales producer for Triad Systems (now Epicor). Luckett has been recognized for his commitment to education and training in the auto care industry with the University of the Aftermarket Founders’ Service Award. He can be reached at [email protected].