OE coils are known for their high failure rates. Engine misfires, rough idle, a decrease in power under acceleration, poor fuel economy, and a check engine light are all signs of an ignition coil that has failed. Read along for more technical information on how to diagnose a failed coil, and why the original equipment manufacturer’s coil may not be the best replacement choice.

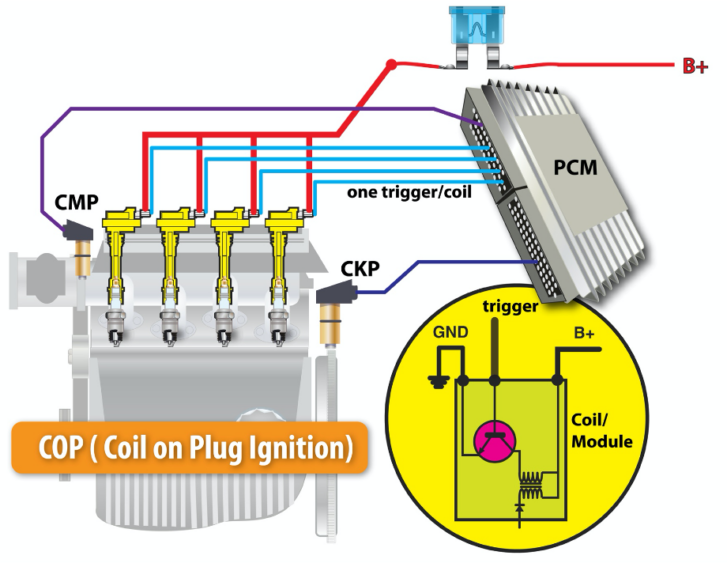

Is the coil driver in the powertrain control module (PCM), or is it in the coil itself? The answer to this may change your diagnostic process. The Coil-On-Plug (COP) system has gained popularity because of its universal application, control precision, and increased capabilities.

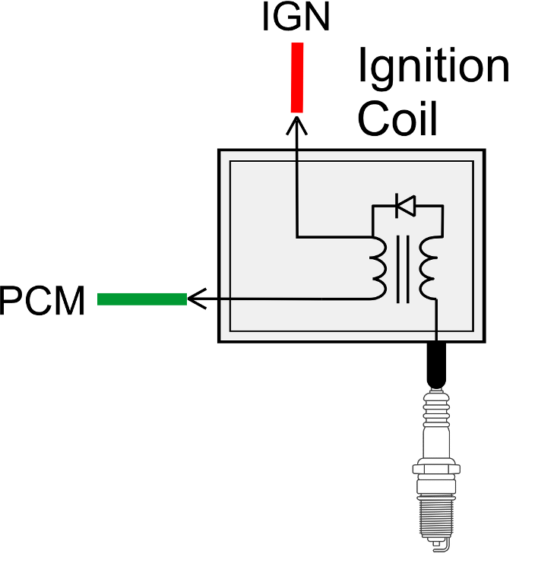

Let’s take a look at a typical Ford “driver-in-PCM” COP coil. The coil is provided a B+ source to one end of the primary winding, and the other end is connected to a low-side driver in the PCM. With this configuration, the PCM internally handles very high current, and also allows for technician access to the primary circuit for various tests.

PCM ignition coil driver circuits can fail due to the high current flowing through them, as well as damage by drivers that stay on too long, creating excessive heat. When replacing a PCM due to a driver failure, it is important to replace the coil as well. Be sure that the coils are disconnected, and do not turn the ignition on unless all damaged coils and the PCM have been replaced.

3- and 4-Wire Coils

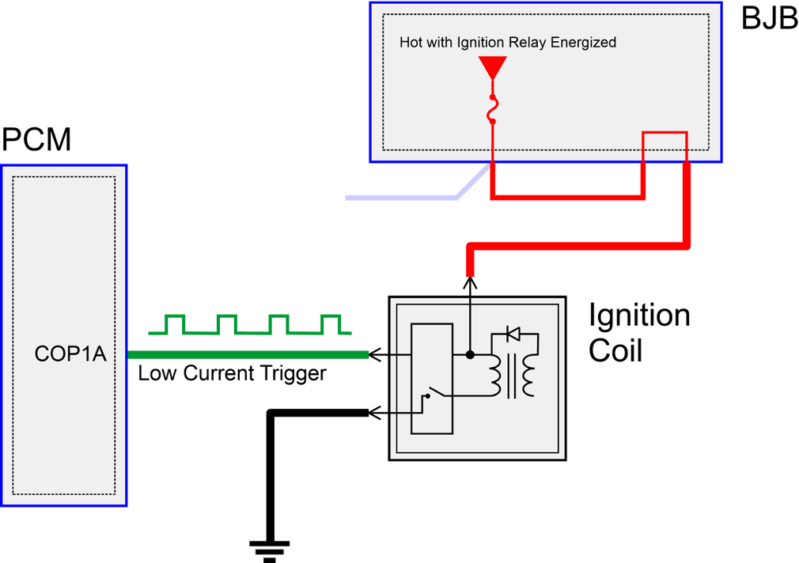

In the last decade, some Fords have been using a 3-wire coil with the driver located in the ignition coil (COP). The circuits are:

· Battery voltage

· Ground

· COPx

When the engine control module applies a voltage (~4-5V) to a coil’s COPx circuit, the internal driver will apply GND and B+ to the primary winding. When the voltage is removed, the internal driver will turn off the primary current. The collapsing magnetic field will induce a high voltage into the secondary winding, causing spark to occur across the spark plug.

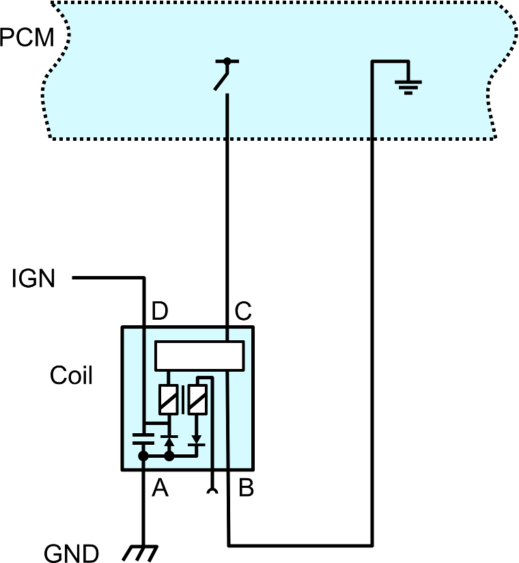

Many GM vehicles have been using 4-wire coils for over a decade. The circuits are:

· IGN B+

· Engine ground

· PCM ground

· Ignition Control (IC)

When the engine control module applies a voltage to a coil’s IC circuit, the internal driver will apply engine ground and B+ to the primary winding. Like the aforementioned Ford coil, when the voltage is removed, the primary current will turn off, collapsing the magnetic field and inducing a high voltage into the secondary winding. It is important to note that the PCM ground is necessary to the internal driver and that it is isolated from the engine ground.

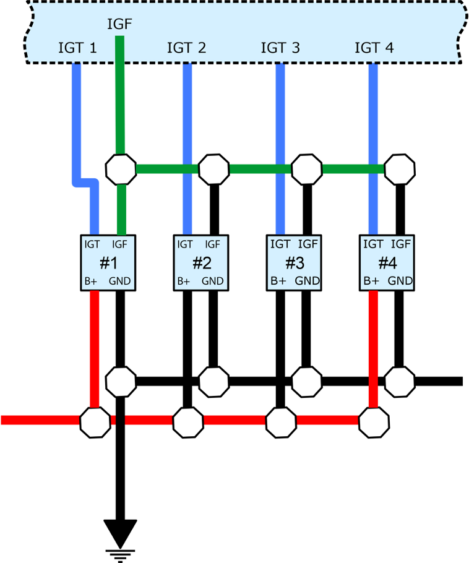

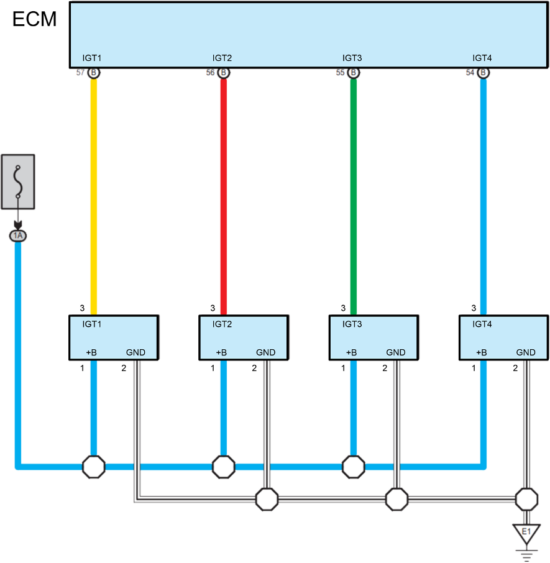

Toyota has been using a 4-wire COP system for a while. The circuits are:

· B+: Battery voltage

· GND: Ground

· IGT: Ignition timing signal

· IGF: Ignition confirmation signal

When the engine control module applies a voltage to a coils IGT circuit, the internal driver will apply GND and B+ to the primary winding. Again, removing the voltage to the IGT circuit causes the internal driver to turn off the primary current. The engine control module applies a 5V signal to the IGF circuits. If the coil driver has determined that the coil has or will fire successfully, the driver will pull the IGT signal low during that period.

Newer Toyota engines (approx. 2019+) are equipped with a 3-wire coil. The circuits are:

· B+: Battery voltage

· GND: Ground

· IGT: Ignition timing signal

When the engine control module applies a voltage to a coils IGT circuit, the internal driver will apply GND and B+ to the primary winding. Like the others, removing the voltage will result in the primary current turning off.

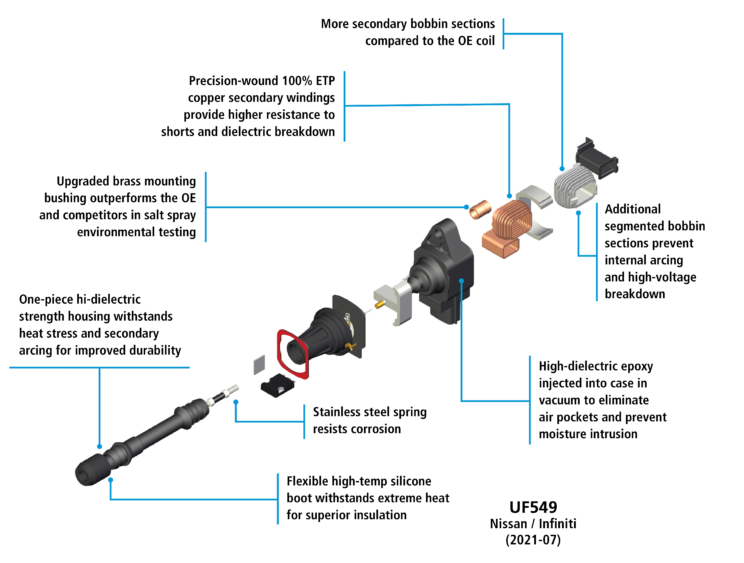

When OE Fails…Trust Standard®

Heat, moisture and corrosion are typical reasons that OE coils fail, and many OE designs can have weak points that lead to product failure. That’s why choosing a replacement coil that’s the same as the one that just failed doesn’t make sense. Blue Streak® engineers evaluate the original part, identify the OE issues, and correct those problems to deliver a better-performing and longer-lasting Coil. All Standard® and Blue Streak® Ignition Coils are subjected to extensive testing both in the lab and on vehicles to make sure parts perform in all conditions, at every RPM, and last.

No matter what type of ignition coil a vehicle has, it will likely fail at some point. With an offering of more than 880 Ignition Coils for both import and domestic vehicles, Standard® and Blue Streak® have the right parts to get your customers back on the road. Over 100 years of experience designing and manufacturing ignition components has made Standard® the brand technicians trust when the OE fails.

When OE Fails…Trust Standard®

This Article is Sponsored By: Standard®